Albemarle Lithium Project

- Project Overview

The Jiangxi Albemarle Lithium Project is a wholly foreign-owned enterprise invested and established in 2016 by Albemarle Corporation (ALB), a global lithium industry giant, with continuous technological upgrading and production capacity expansion. Its core business is the production of battery-grade lithium hydroxide, a critical raw material for new energy vehicle batteries.

Since its establishment in 2016, the enterprise has continuously expanded its scale and upgraded its technologies through multiple rounds of investment. The main projects are as follows:Early-stage Projects: An investment of 0.8 billion yuan was made in 2017 to construct new production lines, and its lithium hydroxide capacity expansion project was fully put into operation in 2019.Core Technological Renovation Projects:2022: With an investment of 0.95 billion yuan, the company launched the technological renovation project for the front-end production lines, aiming to achieve an annual production capacity of 38,000 tons.

- Customer background and challenges

Client Background: The client is Albemarle Corporation (NYSE: ALB), a U.S.-based global lithium industry giant. It is a leading specialty chemicals enterprise with a history of over 100 years and a worldwide business presence. As one of the world’s largest lithium chemical producers, the company not only holds top-tier global lithium resources (such as interests in the Greenbushes Lithium Mine in Australia and the Atacama Salt Lake in Chile) but also has built large-scale lithium salt processing bases across the U.S., China, Australia and other regions. Its target is to increase its lithium conversion capacity to approximately 450,000–500,000 tons per year by 2030.

Challenges: Our company is facilitating the intelligent transformation of the client’s factory, where the entire plant’s lighting fixtures will adopt the Huarong Intelligent Lighting System. This requires conducting on-site surveys of the factory, and formulating a layout plan for the distribution of lighting fixtures and the deployment of system control components.

- Our Solution

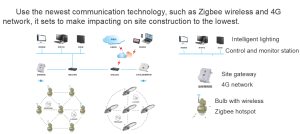

For this project, our company has adopted the independently developed SGS Safety & Industrial Intelligent System to carry out lighting illuminance design and zonal control design for the entire plant. Cutting-edge communication technologies such as Zigbee wireless communication and 4G network are employed to minimize the impact on on-site construction.

- Implementation Process &Timeline

The project kicked off with preliminary technical discussions with the client and the design institute in August 2022, and was delivered to the site in the second half of 2023, spanning over a year. Our company provided one-stop services for the client throughout the entire process, covering project design, order delivery, and subsequent on-site construction.

- Results & Data Highlights

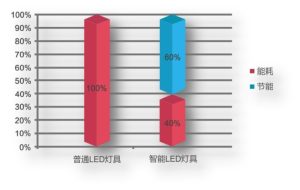

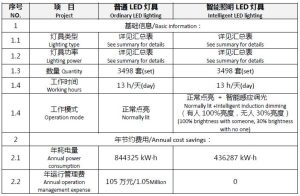

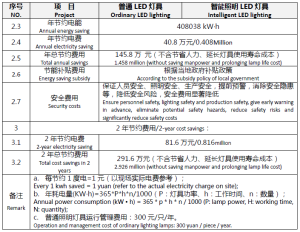

- Through the preset scene, the intelligent control such as on-demand lighting and time sharing lighting can achieve energy saving, emission reduction, cost saving and prolong the service life of lamps and lanterns. At the same time, it can reduce the bearing pressure of the power supply system and extend the service life of the power supply system Intelligent lighting fixtures have 0% ~ 100% accurate dimming function to achieve the purpose of lighting energy saving, reduce enterprise lighting costs, and respond to the call of national energy conservation, emission reduction and green environmental protection.

- Reduce equipment maintenance and labor costs:

1)Intelligent management, realize on-demand lighting through remote automatic or real-time control of lighting terminal, reduce personnel labor intensity and save labor cost;

2)Monitor the operation status of lighting terminal equipment in the plant in real time to reduce the inspection frequency;

3)Intelligent dimming control, reduce the amount of lighting lamps as needed, prolong the average service life of intelligent lamps and reduce equipment maintenance costs.

- Reduce equipment maintenance and labor costs:

1)Intelligent management, realize on-demand lighting through remote automatic or real-time control of lighting terminal, reduce personnel labor intensity and save labor cost;

2)Monitor the operation status of lighting terminal equipment in the plant in real time to reduce the inspection frequency;

3)Intelligent dimming control, reduce the amount of lighting lamps as needed, prolong the average service life of intelligent lamps and reduce equipment maintenance costs.

- Customer Feedback

The implementation of the intelligent lighting project has outstanding social benefits. According to the national strategic layout of energy conservation and consumption reduction at this stage, all enterprises are implementing the project implementation of energy conservation and emission reduction transformation and intelligent manufacturing. The project closely connects the two themes of intelligent manufacturing and energy conservation and emission reduction, and plays a leading role in the application of the whole petrochemical industry;

Intelligent lighting control system is one of the means to solve the global power shortage. It can save limited power consumption by adopting advanced power-saving equipment and perfect power schemes, effectively alleviate the current situation of global energy shortage and achieve the purpose of energy conservation.

According to the energy-saving scheme management of the project, it not only improves the service life of lighting equipment, but also saves about 50% of the total energy, saves electric energy, standard coal energy, reduces CO2 greenhouse gas emission and SO2 gas emission, so as to make some contributions to the national consumption reduction and improvement of living environment:

- Lessons & Insights

With the development of industry, intelligent control has become an urgently needed system for people. Especially for the intelligent transformation of hazardous areas such as petrochemical industry, it can not only realize pre-control in the early stage, reduce risks and save energy. The success of this project benefits from the years of R&D investment in Huarong SGS Intelligent Safety & Industrial System, as well as the determination to promote the market and industrial intelligent transformation.