Explosion-Proof Upgrade of Grain and Oil Plant in Argentina

- Project Overview

WAROM TECHNOLOGY, a leading enterprise in China’s explosion-proof electrical industry, has provided professional on-site visit reports and hidden danger analysis conclusions based on its field inspection of the soybean processing plant of Cargill Grain and Oil (Argentina), a global leading agricultural and food enterprise. It also accurately responded to the plant’s explosion-proof equipment needs by supplying three core product categories—explosion-proof switches, explosion-proof lighting fixtures, and explosion-proof junction boxes, along with supporting on-site technical support services. With the efficient response of “switches delivered within 1 week, lighting fixtures within 2 weeks, and junction boxes put into use within 1 month”, it accurately addresses Cargill’s urgent safety pain points, becoming a typical service case for WAROM Technology to deepen its presence in the explosion-proof market of the South American grain and oil processing industry.

- Customer background and challenges

As a core soybean processing base established by Cargill Grain and Oil in Argentina, this plant was founded in 1990 and is located in the grain and oil industrial belt around Rosario, Santa Fe Province—the core agricultural area of Argentina, approximately 300 kilometers away from the capital Buenos Aires. As a key enterprise in the local agricultural industrial chain, its location concentrates more than 60% of Argentina’s grain and oil processing capacity, with an annual soybean processing capacity of 1.5 million tons. Its products are sold far to South American and European markets. Safe production is directly related to the stability of regional food supply. As a subsidiary plant of an international agricultural giant, it has particularly strict requirements for the safety and compliance of equipment.

After an on-site inspection, WAROM Technology’s technical team formed a detailed on-site visit report, clarifying that Cargill Grain and Oil Plant has multiple fatal safety hazards. Combined with the environmental and production characteristics, it provided targeted equipment solutions. Firstly, the lack of explosion-proof equipment is prominent: switches in the operation area have no explosion-proof certification, cables have no gland sealing, lamps are water-permeable and have no explosion-proof qualification, junction boxes are not equipped with grounding devices, and the soybean dust filling the workshop is explosive, posing extremely high safety risks. Secondly, the environmental adaptability requirements are strict: the plant has high dust concentration and high humidity in the oil processing link, and the local area has an extreme high temperature of 40℃ in summer and as low as -5℃ in winter, posing great challenges to the equipment’s protection and temperature resistance. Thirdly, the standard adaptation requirements are clear: as a large-scale continuous production plant, equipment replacement needs to be closely connected, and products must meet Cargill’s global safety standards, the 220V/380V, 50Hz electrical system in South America, and Argentina’s ATEX certification requirements.

- Our Solution

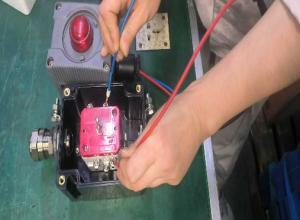

Based on the hazardous environment level and compliance requirements specified in the inspection report, WAROM Technology accurately matched three categories of core explosion-proof products for Cargill Grain and Oil Plant. Explosion-proof switches are divided into two types to adapt to different risk areas: Ex d e IIC T4 grade for areas with flammable gas risks, and Ex tD A21 IP66 grade for dust-intensive areas, both equipped with certified explosion-proof glands to enhance sealing. Explosion-proof lighting fixtures are upgraded to Ex tD A21 IP67 grade, adopting a double-sealing structure and tempered glass cover to solve the water seepage problem, with high luminous efficacy of ≥140lm/W and resistance to temperature differences from -5℃ to 40℃. The BXJ-S series explosion-proof junction boxes adopt a combined structure of flameproof and increased safety, with 304 stainless steel shells resistant to dust corrosion and built-in grounding terminals to eliminate static hazards.

To translate the inspection report conclusions into practical solutions, WAROM Technology, in conjunction with local partners, held a technical exchange meeting with 50 participants in Rosario, Santa Fe Province—Argentina’s core grain and oil processing agglomeration area, approximately 300 kilometers away from Buenos Aires. Participants included technical backbones of Cargill’s plant and representatives of surrounding grain and oil enterprises. The meeting focused on explaining the hidden dangers identified during the inspection, the connection between Cargill’s safety standards and local regulations, and the equipment selection logic, while collecting feedback to optimize product configuration. All products have passed extreme environment tests such as dust resistance and corrosion resistance, with a deviation of core performance parameters ≤ 3%. They have also completed the ATEX international certification in advance to ensure full adaptation to the needs.

- Implementation Process &Timeline

Adopting the principle of “report implementation and rapid response”, WAROM Technology efficiently advanced product supply and delivery:

In early Q3 2025, the technical team went to Argentina to complete the on-site inspection of Cargill Grain and Oil Plant and issued a visit report including a hidden danger list and preliminary suggestions; in the middle of Q3, after confirming the product needs and selection plan through the technical exchange meeting, emergency production scheduling was immediately launched to give priority to ensuring the production capacity of core products.

The delivery nodes were accurately implemented: 7 days after the technical exchange meeting, the explosion-proof switches and supporting glands were delivered to the site of Cargill Grain and Oil Plant via urgent logistics; within 14 days, the explosion-proof lighting fixtures arrived at the port and completed on-site handover; within 1 month, all explosion-proof junction boxes were in place. After each batch of products is delivered, WAROM’s technical engineers arrive at the site simultaneously to provide installation guidance and commissioning services to ensure the rapid adaptation of the equipment. At the end of Q3 2025, all equipment completed installation and commissioning, passed the joint acceptance by Cargill Grain and Oil and the local third-party organization, and was officially put into use.

- Results & Data Highlights

A total of 3 categories and 18 specifications of explosion-proof products were supplied this time, with a 100% delivery completion rate for the whole series, 0 logistics damage rate, and 100% one-time pass rate for installation and commissioning. It accurately fulfilled the delivery commitment of “switches within 1 week, lighting fixtures within 2 weeks, and junction boxes within 1 month”, perfectly connecting with Cargill Grain and Oil Plant’s equipment replacement plan.

In terms of safety, the supplied products have targeted solutions to 8 categories of explosion-proof safety hazards in Cargill Grain and Oil Plant, reducing the explosion risk in relevant areas by more than 90%, and all performance indicators meet IEC international standards, Cargill’s global safety specifications and Argentine industrial regulations. In terms of cooperation value, this accurate service based on on-site inspection radiates the core grain and oil producing areas of South America relying on the Rosario exchange meeting, helping WAROM Technology successfully enter the explosion-proof market of the South American grain and oil processing industry, laying the foundation for the subsequent development of markets in neighboring countries such as Brazil and Uruguay, and strengthening the professional image of Chinese explosion-proof brands.

- Lessons & Insights

The cooperation with Cargill Grain and Oil this time confirms the service concept of “based on on-site inspection and focused on accurate response”. Conducting in-depth on-site hidden danger investigation and forming professional reports is the prerequisite for accurately matching product needs; flexible production scheduling and urgent logistics support are the keys to fulfilling delivery commitments; and product compliance and localized services are the core support for the implementation of overseas cooperation. In the future, WAROM Technology will continue to take on-site research as the entry point, providing more targeted explosion-proof equipment solutions for international customers in fields such as grain and oil, and chemical industry.