Hail & Gasha Onshore Project

- Project Overview

As a benchmark enterprise in the field of explosion-proof lamps and electrical equipment in China, WAROM TECHNOLOGY INCORPORATED COMPANY (hereinafter referred to as “Warom Technology”) successfully awarded the supply contract of the Low Voltage Distribution Board for Hazardous Area in Hail & Gasha Onshore Project in UAE. The total project amount exceeds 2.3 million EURO, and this collaboration not only marks a milestone in Huaring Technology’s deepening presence in the Middle Eastern market but also highlights the department’s capability in collaborative execution of large-scale projects.

- Customer background and challenges

Client Background: As the EPC contractor for the Hail & Gasha Onshore project under ADNOC, Tecnimont places stringent requirements on the timeliness and technical compliance of equipment delivery, which directly impacts the overall project progress.

Core Challenges:

- The project has an urgent deadline with a very short cycle, as the period from contract signing to delivery is less than five months

- The technical documentation is also extremely extensive, with a total of 99 project files, 81 of which are technical documents. This results in batch modifications significantly impacting the approval and clearance of all technical documents, where a single change affects the entire system

- It is necessary to balance “rapid response” with “quality compliance” to avoid compromising product performance due to rushed production

- Our Solution

- Pre material preparation: Breaking the conventional mode of “preparing materials after the drawings are fully approved”, starting the procurement of BXJ-S junction box and HRMD92 junction box shells and core material stocking at the CODE B stage (key node of drawing approval), saving time in the production process

- Accelerate technical communication, drawing approval and confirmation time nodes, quickly pass all key technical points through integrated meeting discussions and sample file submission and approval, promote the priority production of all shells, synchronously improve various details and differences, and promote the steady and orderly progress of technical drawing issuance and production

- Reasonably plan the production quantity and completion time of each batch according to the customer’s on-site requirements, effectively arrange final inspection and batch delivery, and ensure the orderly implementation of on-site plans

- Implementation Process & Timeline

- March April 2025, the submission of technical document samples and multiple technical clarification meetings established the requirements and blueprint for modular formatting of all subsequent technical documents, setting the tone for subsequent batch submissions and approvals

- On May 16, 2025, the PIM meeting set the direction for all topics and entered the shell stocking and processing stage in an orderly and steady manner according to the plan

- In July 2025, the first sample will be completed and the customer will be invited to dispatch inspectors for on-site inspection, setting the tone for subsequent batch production confirmation of the first piece

- From August to October 2025, frequent technical and business changes occurred at the customer’s site. Our company actively responded, resolved and continued to promote production matters as soon as possible, and later learned about the customer’s planned time sequence for each distribution box on site. We flexibly adjusted the workshop load and ensured the highest quality and most comprehensive and detailed self-nspection while meeting the customer’s delivery deadline. We ensured that the inspection passed in one go and quickly entered the delivery stage. By the end of October 2025, we will send the first batch of 69 distribution boxes according to the customer’s normal arrangement

- Based on the customer’s on-site time requirements and the actual production capacity of the workshop, the batches will be adjusted to be delivered in batches before the end of January 2026, with each detailed time point implemented one by one, in order to set the delivery schedule for the entire project

- Achievements and Data Demonstration

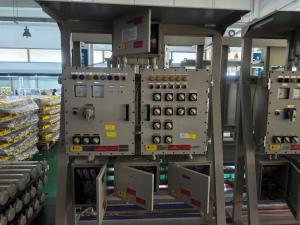

- Successfully delivered a large quantity of BXJ-S junction boxes and HRMD92 distribution boxes. The products have been accepted by the customer, and the technical parameters and performance indicators meet the final confirmation requirements without any quality objections

- Compared to similar projects in the industry, the regular cycle is shortened by more than 40%, and the drawing modification confirmation cycle is shortened by 50% compared to the regular cycle.

- The delivery time is 50% ahead of the project site plan, greatly meeting the temporary demand for early planning that may exist on site

- Customer Feedback

Based on multiple meetings and communications with the client, the client has always praised Warom’s delivery speed and quality assurance, and has expressed great affirmation and praise for the support and response provided throughout the project; A professional, efficient attitude and strong execution ability provide key guarantees for the subsequent progress of the project, making it a trustworthy long-term partner

- Experiences Summary & Insights

The increasing number of international projects mea1. Pre planning is the core of short cycle projects: under the premise of compliance, breaking the inherent thinking of “approval before production” and locking in key materials (such as shells and core components) in advance can effectively offset the delivery pressure caused by short cycles

- The number of files will greatly affect the overall project schedule, and it is necessary to constantly monitor the submission and approval progress of the overall files. Any details that may be affected need to be controlled in real time and minimized as much as possible

- During the production phase, it is necessary to collaborate with various departments, pay attention to the progress of the process, understand the work status, progress, and capacity load of the workshop, and share real-time information with the project execution department to adjust and improve current policy plans through joint efforts and improve delivery efficiency

- Customer win-win awareness is the foundation of long-term cooperation: actively cooperating with customer needs adjustment in the project, resolving change risks with professional ability, not only can win customer recognition, but also lay a solid foundation for subsequent cooperation.