Ras Laffan Project

- Project Overview

As a benchmark enterprise in the field of explosion-proof lamps and electrical equipment in China, WAROM TECHNOLOGY INCORPORATED COMPANY (hereinafter referred to as “Huarong Technology”) successfully won the core supply contract of the RAS LAFFAN Project in Qatar. This contract covers multiple sets of electrical product packages, specifically including: explosion-proof lamps, operation columns, distribution boxes, junction boxes, three-proof distribution boxes, grounding materials and other comprehensive packages. The total project amount exceeds 5.5 million US dollars, with an execution period of three years and phased supply. This cooperation is not only a milestone for Huarong Technology in deepening its presence in the Middle East energy market, but also highlights the core fulfillment capabilities of “Made in China” in international high-end energy engineering.

- Customer background and challenges

The clients are local energy giants and supporting enterprises that have been laid out around the natural gas industry. These clients have formed a clear demand for explosion-proof products by relying on the world-class LNG industrial base, but they also face multiple challenges such as safety compliance and equipment compatibility, which will affect your cooperation and exchanges. The following is the specific analysis:

1、Customer background

(1)The customer base is mainly composed of energy giants, and most of them are joint ventures

Ras Laffan’s core customers are mainly concentrated in high-risk fields such as LNG production, gas-to-oil conversion, and condensate refining, and most of them are joint ventures between local Qatari enterprises and international energy giants. Core customers include QatarGas and RasGas, both of which control dozens of LNG production lines and are the largest demanders of explosion-proof equipment. There are also project companies such as Antelope Gas to Oil and Pearl Gas to Oil, as well as Gulf Gas Company and condensate Oil Refinery, etc. In addition, the operators of loading and unloading equipment at Ras Lavan Port, local seawater desalination plants and other supporting facilities enterprises also need explosion-proof instruments, switches and other products to ensure operation safety, thus forming a diversified customer matrix.

(2)The demand scenarios for explosion-proof products are diverse and have strong essential needs

The entire production process of these customers is subject to the risk of explosive gas leakage, and the demand for explosion-proof products runs through all links such as production, storage and transportation. For instance, in LNG liquefaction plants, explosion-proof sensors and dew point meters are needed to control production parameters. Previously, high-precision dew point meters of American brands have been used here to stabilize the water content of natural gas. The reaction workshop of the gas-to-oil factory needs to be equipped with explosion-proof motors and explosion-proof lamps. The port loading and unloading area requires explosion-proof lifting equipment, junction boxes, etc., to prevent explosions caused by equipment sparks during loading and unloading. Moreover, the production lines of these customers mostly operate continuously for 24 hours. Explosion-proof products are not only the core equipment for ensuring production but also a hard requirement for meeting safety regulations. The demand for replacement and supplementation persists

(3)Customers are subject to both international and local standards

As a world-class energy base, Ras Lavan’s customers have extremely high standards for explosion-proof products. On the one hand, it must comply with internationally recognized explosion-proof certification standards such as IECEx, and some equipment also needs to meet the relevant regulations of ATEX certification. On the other hand, it is necessary to pass the mandatory CD certification of Qatar, where the explosion-proof performance, environmental adaptability and other indicators of the products are reviewed by the Qatar Standardization Organization (QGOSM). For instance, products need to pass explosion-proof tests conducted by local laboratories and temperature tests that can withstand extreme environments of 55℃. When purchasing, customers will strictly verify these certification documents to avoid compliance risks.

2、The main challenges faced by customers

(1)The equipment needs to be adapted to extreme working conditions and has strict requirements for product performance

Ras Laffan is located in the Gulf area. It not only has the climatic characteristics of high temperature and high humidity, but also some equipment needs to come into contact with corrosive media such as seawater and natural gas condensate oil. The explosion-proof products used by the customer must not only resist the wear of the equipment casing caused by desert dust, but also have strong anti-corrosion capabilities to prevent the failure of explosion-proof seals due to the erosion of seawater or chemical media. Meanwhile, the cryogenic environment in LNG production may also affect the stability of electronic components in explosion-proof equipment. For instance, dew point meters need to accurately monitor data at low temperatures. This requires customers to screen high-end products that can adapt to multiple working conditions when purchasing. However, the range of products that meet such strict requirements is relatively narrow, and they may also face higher procurement costs.

(2)The certification process is complex, which affects the efficiency of equipment procurement and replacement

The CD certification in Qatar is a necessary step for explosion-proof products to enter the local market. This process not only requires enterprises to submit a large number of documents such as product test reports and ISO 9001 system certificates, but may also involve local re-testing of samples and factory audits. The entire cycle usually takes about six months. If the customer urgently needs to replace the faulty explosion-proof equipment, the lengthy certification process may cause the production line to shut down. However, if uncertified products are purchased, once they are investigated and dealt with by the regulatory authorities, they will face heavy fines and the risk of project suspension, which puts customers in a dilemma between the timeliness and compliance of equipment procurement.

(3)Under global competition and cost pressure, it is necessary to balance the cost performance of equipment

At present, LNG exporting countries such as Australia and the United States are squeezing market share. To maintain their competitiveness, Lasafan’s customers need to control production costs. However, the procurement cost of explosion-proof products remains high: on the one hand, high-quality explosion-proof products mostly rely on imports, and with the addition of costs such as certification and transportation, the procurement price has long been at a high level; On the other hand, the production lines of customers are constantly expanding (for instance, QatarGas has repeatedly advanced production line expansion projects), and the purchase volume of explosion-proof equipment has increased simultaneously, further intensifying the cost pressure. In addition, the maintenance and repair of some core explosion-proof equipment rely on the technical support of the original factory, and the subsequent maintenance costs also put customers under continuous expenditure pressure.

- Our Solution

1、Core positioning of the solution

With “compliance first, working condition adaptation, and full-chain guarantee” as the core, in response to the characteristics of high temperature, high humidity, high corrosion, and continuous production scenarios in the Lasafan LNG industry, we integrate a full range of products including explosion-proof lamps, operation columns, and distribution boxes, providing a comprehensive solution of “one-stop procurement + customized adaptation + localized services” Address the four core pain points of customer compliance certification, equipment stability, supply chain efficiency and cost control.

2、Core product portfolio and scene adaptation

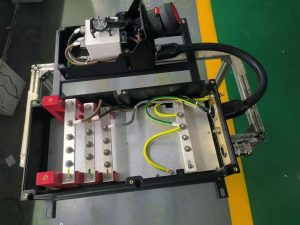

(1)A full range of product matrix

3、Customized adaptation design (optimized for extreme working conditions

(1) Material customization: For all outdoor/seaside scene products, the shell is uniformly made of 304/316 stainless steel with fluorocarbon coating. The core components (such as seals) are made of special rubber that can withstand low temperatures from -40 ℃ to high temperatures from 55℃, suitable for the high-temperature, high-humidity and salt spray corrosion environment of Ras Lavan.

(2) Function customization: According to the control requirements of the customer’s equipment, customize the button layout of the operation column and the protection module of the distribution box. For cryogenic environments (such as LNG storage areas), low-temperature start-up type distribution boxes (with built-in heating modules to prevent components from cracking due to freezing) are provided.

(3) Installation Customization: Explosion-proof lamps can be customized for three installation methods: wall-mounted, ceiling-mounted, and pole-mounted. The junction box reserves hoisting holes, making it suitable for complex installation scenarios such as high altitudes and confined Spaces.

4、The core advantages of the solution

(1)Full coverage of compliance certification, resolving certification barriers

All our products have completed the IECEx+ATEX + Qatar CD certifications ahead of schedule. We provide complete certification reports, test data and local audit documents. Customers can put them into use directly after purchase without the need for an additional 6-month certification cycle, thus avoiding compliance risks. Every year, we cooperate with customers to complete the re-inspection of equipment compliance, provide original factory technical support, and ensure that the products comply with the regulatory requirements of QGOSM (Qatar Standardization Organization) in the long term.

(2)It has strong adaptability to working conditions, ensuring continuous production

The product has passed the verification of four extreme environments: “high-temperature aging test, salt spray corrosion test, dust protection test, and vibration test”, with a failure rate of ≤0.5%. It is compatible with the 24-hour continuous production mode of Ras Lavan, reducing the downtime losses caused by equipment failures. The core products (such as explosion-proof lamps and distribution boxes) adopt a modular design. When a fault occurs, components can be quickly replaced, with a repair time of no more than 2 hours, which is far lower than the industry average.

(3)One-stop procurement + supply chain guarantee to enhance efficiency

Integrating the full range of explosion-proof products, customers do not need to deal with multiple suppliers, achieving “one-time order, full set delivery”, reducing procurement communication costs and delivery cycles (overall delivery cycle ≤30 days, 50% shorter than the industry average).

In response to the production line expansion needs of Ras Lavan customers, we offer the “safety stock reservation” service. Core products are stocked in advance, and the emergency replenishment cycle is ≤7 days, addressing the risk of supply chain disruption. Logistics adopts the “direct sea freight + local warehousing” model. Goods are directly delivered to the designated factory area in Ras Lavan Industrial City. We cooperate with customs clearance specialists to assist in handling customs declaration procedures to avoid transportation delays.

5、Full life-cycle services, cost reduction and efficiency improvement

(1) Pre-sale: Based on the technical requirements of the customer’s bidding and tendering, provide product selection plans and installation plans to avoid waste caused by improper selection.

(2) During the sales process: We offer free installation guidance and equipment commissioning services to ensure the product can be put into use quickly.

(3) After-sales service: Set up a branch in the Middle East to provide on-site technical services;

(4) Cost optimization: By bulk purchasing and modular production, the unit price of products is reduced, and the overall procurement cost for customers is lowered by 15% to 20%.

6、Cooperation guarantee commitment

(1) Product quality commitment: All products come with a 3-year warranty. During the warranty period, any non-human-caused damage will be replaced free of charge.

(2) Compliance Commitment: We ensure that our products comply with the Qatar CD certification and IECEx standards in the long term. If customers are punished due to certification issues, we will bear all losses.

(3) Service Commitment: On-site technical support can be provided.

- Implementation Process & Timeline

1、Bidding and tendering stage

Form a dedicated team, closely adhere to the requirements of certification and extreme working conditions, prepare all necessary qualifications and cases, highlight the full-series customization of products and full-cycle services, and answer core concerns during the defense.

2、Winning the bid stage

Refine the requirements and delivery nodes, sign the product contract, stipulate a three-year warranty and delivery method, reserve supplementary terms, and lay the foundation for long-term cooperation.

3、Execution stage

(1)Initial contract execution:

Break down requirements to optimize products, promote cross-departmental collaboration, regularly synchronize with customers, and collect feedback on-site.

(2)Multiple rounds of supplementary implementation

In response to demands such as cryogenic treatment, expansion, and emergency response successively, we quickly customized and delivered, optimized product performance, and ultimately signed a long-term framework agreement.

4、Production stage

Formulate customized plans, ensure the procurement of compliant materials, activate emergency production lines, and strictly control quality and adaptability to working conditions.

5、Inspection stage

Jointly inspect the goods in accordance with the dual standards, verify the certification, materials and parameters, issue a report, and ensure that the supplementary products are compatible.

6、Delivery stage

Adopting a sea transportation + local warehousing model, we deliver in batches and provide document and installation guidance simultaneously to facilitate rapid commissioning.

- Results & Data Highlights

The LNG liquefaction plant (La Slavan core project) previously faced problems such as frequent damage to explosion-proof lamps and corrosion short circuits in distribution boxes. After adopting our comprehensive solution, the equipment failure rate dropped from the original 8% to 0.3%, the annual downtime was reduced by 120 hours, and economic losses of over one million US dollars were avoided. As the product has completed the CD certification ahead of schedule, the procurement delivery cycle has been shortened from 90 days to 25 days, in line with the progress of the production line expansion. Through one-stop procurement, customers’ procurement costs are reduced by 18% and operation and maintenance costs by 22%.

- Customer Feedback

As a continuous LNG production enterprise, we have long been plagued by three major pain points: First, the certification process for explosion-proof products is cumbersome, and new equipment needs to wait for half a year after purchase before it can be used in compliance. Second, in high-temperature and high-salt spray environments, the failure rate of traditional equipment is as high as 8%, and frequent shutdowns result in huge losses. Thirdly, it is necessary to contact more than five suppliers to purchase different types of explosion-proof products, and the communication and coordination costs are extremely high. After adopting your company’s comprehensive solution, these problems have been fundamentally resolved: the entire series of products have completed the Qatar CD certification ahead of schedule, and the delivery and installation can be completed within the contract delivery period after purchase, fully matching the progress of our production line expansion. Since the equipment was put into operation for one year, the failure rate has been significantly reduced. Especially for the explosion-proof lamps and distribution boxes, there has been no corrosion or damage in the salt spray environment by the seaside, ensuring 24-hour continuous production. The one-stop procurement model has increased our procurement efficiency by 60%, eliminating the need to divert our energy to connect with multiple suppliers.

- Lessons & Insights

- Accurately identifying pain points is the prerequisite for the implementation of solutions

(1) In response to the core pain points of Ras Lavan customers, such as high compliance thresholds and long certification cycles, we completed the IECEx+ATEX+CD triple certification in advance, saving customers additional certification costs and time, and becoming the core stepping stone for cooperation.

(2) Focusing on the scene characteristics of “high temperature, high humidity, high corrosion, and continuous production”, all products are optimized around “anti-corrosion, high-temperature resistance, and high stability”, rather than simply providing standardized products, to ensure the targeted nature of the solutions.

- Dual-wheel drive of products and services to build core competitiveness

(1) Product side: We meet the diverse needs of customers with a “full series matrix + customized adaptation”, covering the entire production process. Moreover, through customized design in terms of materials, functions, and installation, we solve the equipment adaptation problems under extreme working conditions.

(2) Server side: Breaking the single model of “selling products”, it extends to the full life cycle service including on-site investigation before sale, installation and commissioning during sale, and local response after sale. Especially the establishment of local service points of Lasafan has solved the urgent demand of customers for “quick repair”.

- Supply chain and cost optimization to enhance customer cooperation stickiness

(1) At the supply chain level: Through the “direct sea freight + local warehousing + reserved safety stock” model, the delivery cycle has been compressed from the industry average of 90 days to 30 days, and the emergency replenishment cycle is ≤7 days, meeting the “zero interruption” demand of customers for continuous production.

(2) Cost aspect: By integrating mass production and one-stop procurement to reduce unit prices, and adding value-added services such as trade-in and operation and maintenance training, we can achieve a dual reduction in “procurement costs and operation and maintenance costs” for customers, thereby enhancing the long-term value of cooperation.