Tilenga Project

- Project Overview

Total E&P Uganda B.V. (COMPANY), along with PARTICIPANTS are developing the Tilenga Project as part of the Lake Albert Development in Uganda.

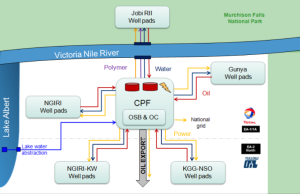

The development is situated in an environmentally sensitive region with a number of the Wellpads located within the Murchison Falls National Park (MFNP), and the remaining Wellpads and Central Processing Facility (CPF), including associated operational camp and support base, located to the South of the Park

The Tilenga Upstream Facilities Project will feed the East African Crude Oil Pipeline (EACOP) transporting oil to the coast in Tanzania.

The purpose of the Project is to provide:

- Onshore facilities for the production, storage and export of heavy and waxy crude oil through a CPF,multiple Wellpads and associated flow line and pipeline systems

- Facilities for re-injection of produced water

- Operational Support Base and Operators’ Camp for field operations

- Lake water abstraction facilities

- Victoria Nile river crossing facilities

The PLANT shall have a design life of 25 years for an oil plateau of 190,000 bpdA schematic of the Project is shown in Figure 1

- Customer background and challenges

As the leading operator, TotalEnergies, a top global energy company, has established a stringent safety management system covering the entire lifecycle of equipment. It imposes a “zero-tolerance” requirement for the international certification, performance stability, and scenario adaptability of explosion-proof lighting products. Based on its extensive experience in overseas projects, the joint construction partner, CNOOC, particularly emphasizes the convenience of localized operation and maintenance as well as the energy-saving benefits of lighting fixtures. Additionally, as the regulatory authority, the Uganda Petroleum Authority requires all lighting equipment to undergo on-site explosion-proof performance verification by its designated third-party institutions and comply with the ecological and environmental standards of the East African region.

Dual Hazardous Environment Overlap: The project site simultaneously features Zone 1 explosive gas environments (methane, ethane, etc., released from crude oil) and Zone 21 dust environments (mineral dust generated by drilling). Conventional explosion-proof lighting fixtures struggle to meet the dual protective requirements for both gases and dust. The wellpads within Murchison Falls National Park further demand that lighting fixtures operate without excessive noise and produce no ultraviolet light pollution to avoid disturbing wildlife habitats.

Dual Thresholds of International Standards and Local Regulations: Lighting fixtures must simultaneously comply with the IEC 60079 series of international standards and the GB 3836.1-2021 Chinese standard. Their explosion-proof rating must reach at least II CT4, with a maximum surface temperature ≤120°C. Additionally, they must obtain both EU ATEX certification and African SONCAP certification. The certification process is complex, with an extremely tight timeline of only 90 days for completion.

Stringent Requirements for Extreme Operating Conditions Adaptation: Uganda experiences daily temperature variations of up to 25°C, with concentrated rainfall during the rainy season accompanied by intense sandstorms. Lighting fixtures must operate reliably in temperatures ranging from -20°C to 60°C with humidity up to 95%. Their dust and water ingress protection rating must reach IP66 or higher. Furthermore, they must possess structural strength capable of withstanding magnitude 7 earthquakes and wind speeds equivalent to a Category 12 typhoon.

- OurSolution

Faced with the multiple challenges of the project, we have established a dedicated team comprising explosion-proof structural engineers and international certification experts. Centered on customized R&D, we have designed both explosion-proof and non-explosion-proof product series, creating an integrated solution that covers “lighting systems, electrical systems, plugs with lamp poles, and more.”

Explosion-Proof Lighting System:

The core configuration includes WAROM luminaires such as the BAT86 floodlight and streetlights.

Electrical Components:

These include the BXJ8050 series explosion-proof control boxes, BXJ91 explosion-proof high-voltage junction boxes, BXM(D)8050 explosion-proof distribution boxes, non-explosion-proof FXMD distribution boxes, as well as a combination of explosion-proof and non-explosion-proof plugs and accessories.

- Results & Data Highlights

As a leading Chinese supplier of explosion-proof lighting and electrical products, WAROM TECHNOLOGY INCORPORATED COMPANY was awarded the contract in 2023 for the Ugandan Tilenga Project, securing the lighting package (including explosion-proof lighting, weatherproof lighting, plugs, and lighting control boxes) and the distribution box package (comprising over 800 distribution boxes and junction boxes) under the EPC contractor McDermott. The contract spans three years of supply with a total value exceeding USD 3.2 million. Currently, seven batches of the lighting package and eight batches of the distribution box package have completed all processes, including production and inspection. A portion of the goods has already been shipped, with the remainder awaiting dispatch.

Additionally, the company was awarded a bulk materials package contract (including lighting fixtures, lamp posts, distribution boxes, junction boxes, high-voltage junction boxes, plugs, grounding materials, etc.) under the EPC contractor Sinopec, with a contract value exceeding RMB 20 million. So far, five batches of goods have been shipped, and the sixth and seventh batches are currently in production. This contract is scheduled for delivery over four years and is expected to be fully completed by 2028.

- Results & Data Highlights

Through the implementation of customized explosion-proof lighting solutions, the project’s lighting system has achieved breakthroughs in safety performance, operational efficiency, and cost control, exceeding client expectations across all metrics:

Zero Safety Incidents**: Ensuring robust protection without any accidents.

Significant Improvement in Energy Efficiency**: Delivering substantial energy-saving benefits.

Drastic Reduction in Operational and Maintenance Costs**: Effectively lowering overall lifecycle expenses.

Adaptability to Extreme Environments**: All lighting fixtures have proven stable under Uganda’s rainy season and high-temperature conditions, operating reliably in environments of 60°C, heavy rain, and sandstorms. The illumination attenuation rate remained below 5%, with no abnormalities in dust and waterproof performance.

- Customer Feedback

“The safe operation of the Tilenga project hinges on meticulous attention to every detail, and explosion-proof lighting, as a fundamental safety measure, is of paramount importance. The FB series explosion-proof luminaires supplied by our Chinese partner not only passed TotalEnergies’ most stringent global explosion-proof performance tests but also demonstrated exceptional stability under Uganda’s extreme operating conditions. In particular, the intelligent lighting system enabled us to achieve precise control over lighting energy consumption.”

- Lessons & Insights

Bid Stage:

Review and clarify technical requirements and commercial terms during the pre-bid phase.

Post-Award Execution:

Organize SDL documentation details and submission schedules, ensure timely arrangement of payment documents, monitor production timelines, oversee inspection processes, verify packaging requirements, and manage shipments.

Optimize Time Management and Enhance Work Efficiency:

Allocate time reasonably between project follow-ups and scattered order handling to avoid conflicts.

Develop the habit of maintaining a work log, simultaneously recording unprocessed emails and pending tasks to ensure no important or urgent work is overlooked.

Focus on Key Tasks:

Create a project document submission tracker.

Prioritize tasks based on urgency and importance—categorizing them as “urgent and important,” “urgent but not important,” or “important but not urgent”—to ensure core work is addressed first.

Participate in weekly project meetings, promptly update project logs, and communicate the latest status and issues.