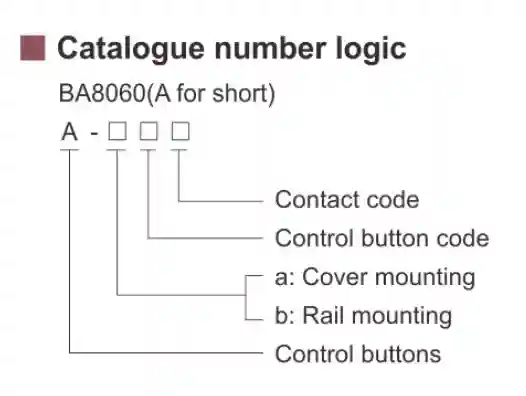

BA8060 Series Control Buttions

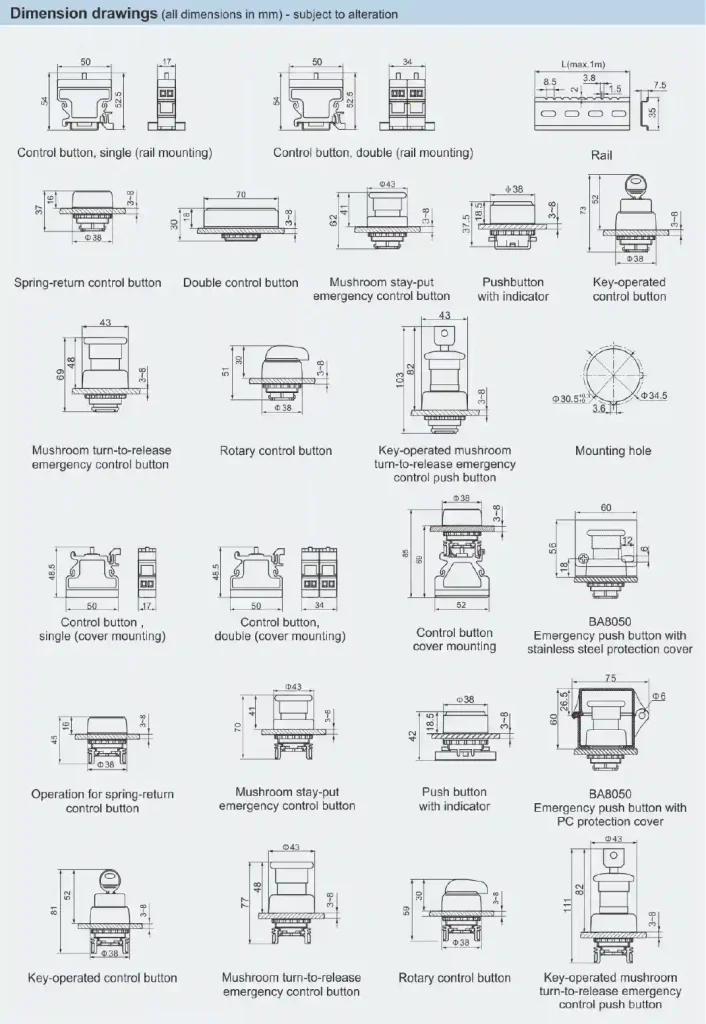

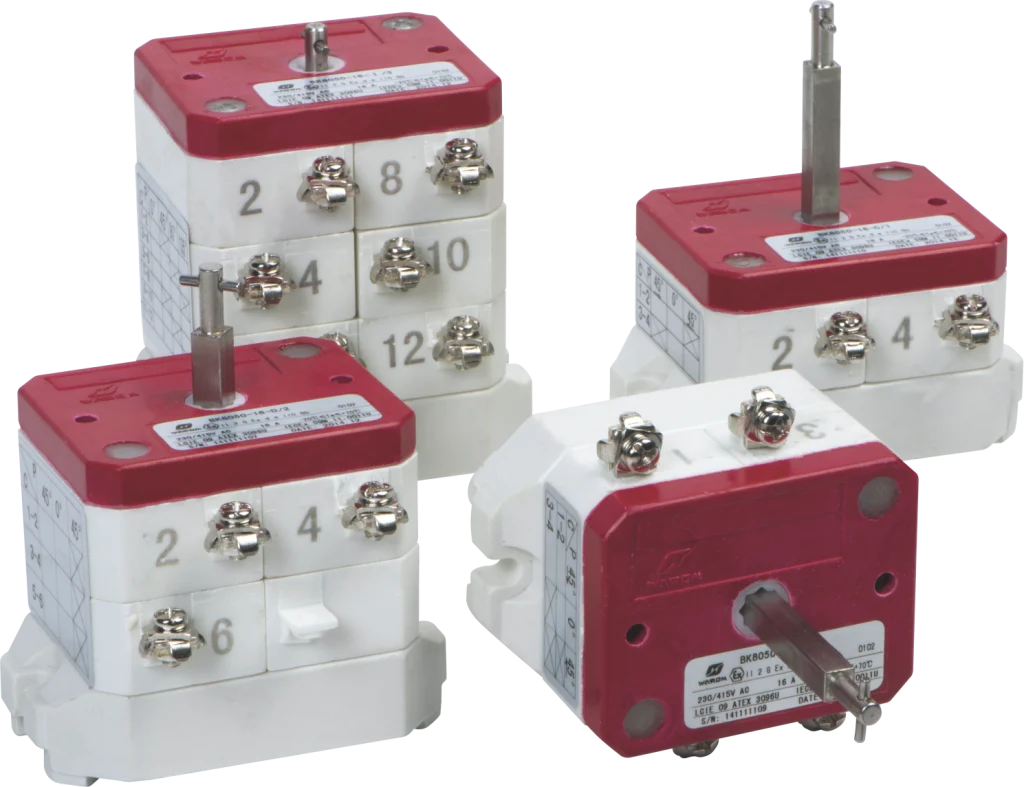

- ◆Flexible & Versatile: Explosion proof control buttons supports flexible installation and is available in eight different configurations to suit various needs.

- ◆Prominent Emergency Stop: Mushroom stay-put emergency control button features a highly visible for the most direct and rapid safety intervention in critical situations.

- ◆Robust & Reliable: These flameproof push buttons boast a simple, durable design that minimizes failures, leading to reduced maintenance and lower lifetime costs.

- ◆Integrated Solutions: Can be assembled into custom explosion-proof push button stations for advanced multi-signal control applications.

TECHNICAL DATA

Explosion Protection Type

Standards: CENELEC, IEC, NEC

Zones: Zone 1 and Zone 2; Zone 21 and Zone 22; Class I, Zone 1 and Zone 2; Class I, Division 2, Groups A, B, C, D

Explosion Protection Ratings:

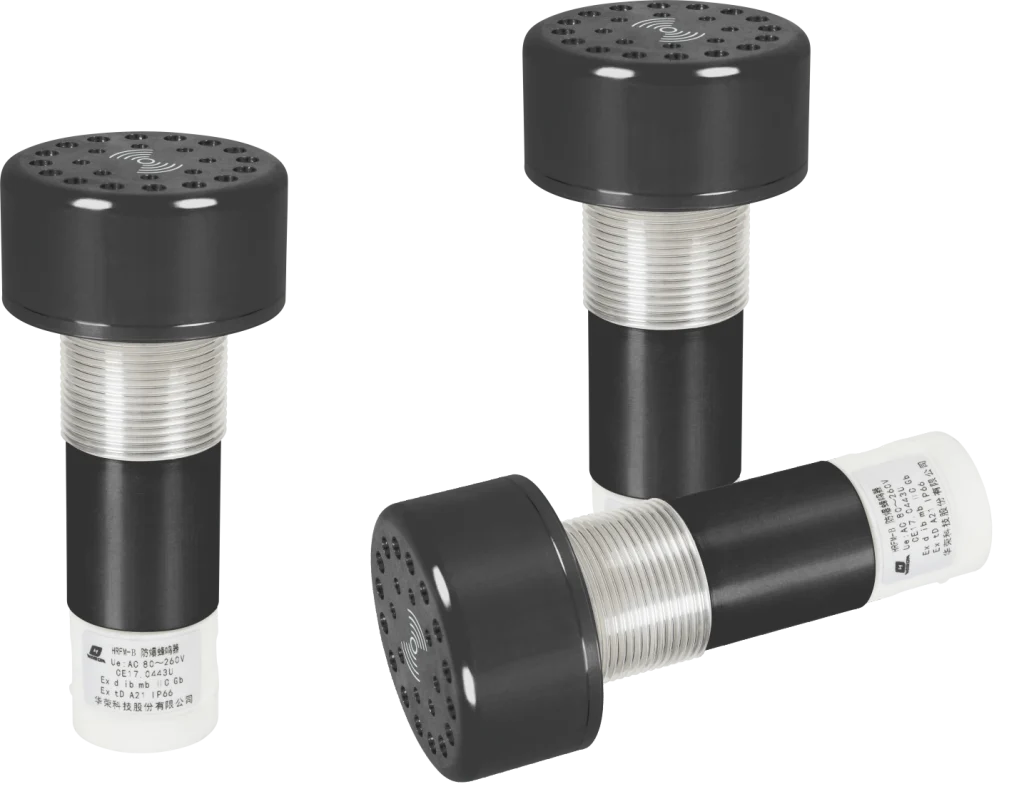

- IECEx (Gas): Ex db eb IIC Gb

- ATEX (Gas): II 2 G Ex db eb IIC Gb

Product Parameters

Material: Polyamide (PA66)

Rated Voltage: 500V AC

Rated Current: 10A

Switch Capacity:

- AC15: Ue 480V/Ie 2.5A; Ue 240V/Ie 5A

- DC13: Ue 240V/Ie 0.5A; Ue 24V/Ie 5A

Product Classification & Origin

HS code: 853710

Country of Origin: China

Applicable Industries

Heavy Industries: Across heavy industries from oil and gas to petrochemical and other industries where flammable elements are a constant threat.

Function: Designed to solve the core issue of potentially introducing an ignition source during manual operations in the most hazardous environments.

Safety: Certified flameproof design ensures it will not become an ignition source, ensuring production processes are carried out safely, efficiently, and reliably.

Credibility

Certifications: Certified to ATEX, IECEx, EAC and more; meeting stringent global requirements.

Reliability: Engineered for reliable performance even in damp, vibrating, and corrosive harsh environments. It acts as a critical first line of manual defense in modern industrial safety systems.

FAQ

Q1: How to select a suitable explosion-proof push button?

A1: Selection should be based on the following criteria:

- Explosion-proof & IP Ratings: Match the marking and IP rating to your site’s hazardous substances (gases/dust).

- Function & Build: Select function (e.g., NO/Start, NC/Stop, E-Stop, illuminated), material, and color.

- Contacts: Specify the number of NO/NC contact sets needed.

- Certifications: Confirm compliance with target market standards (e.g., ATEX, IECEx).

Q2: What are the specific requirements for an ex emergency stop button?

A2: Emergency stop buttons must comply with mandatory safety standards and possess:

- Direct-Action Contact Break: Mechanically severs the load circuit.

- Maintained Locked State: Requires a manual reset action (e.g., twist-to-release).

- High-Visibility Design: Red mushroom head, ideally on a yellow background.

Q3: Can operational labels be temporarily attached to the housing of flameproof push buttons in a chemical plant?

A3: Not recommended. Labels can impair heat dissipation and block critical markings. If required, use temperature-resistant and anti-static materials. The best practice is to select buttons with a custom nameplate slot or laser engraving.

Q4: What could be the potential reasons if the equipment does not respond after pressing the buttons?

A4: Troubleshoot following these steps (ensure power is isolated before proceeding):

- Check Wiring: Inspect for loose or disconnected internal wiring.

- Check Contacts: Examine if the contacts are oxidized or burnt.

- Check the Load: Verify the health of the relay or contactor coil being controlled.

- Check the Button Mechanism: Determine if the mechanical assembly is jammed or damaged.