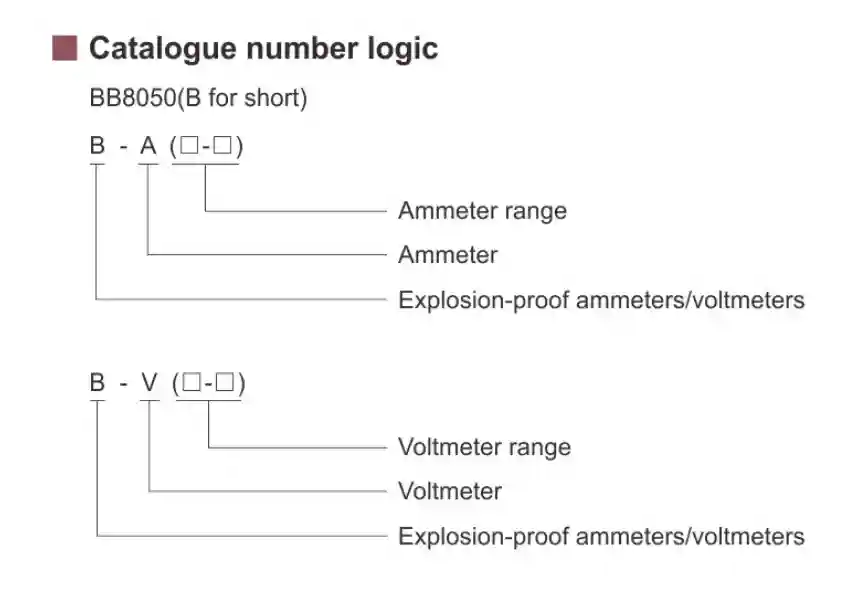

BB8050 Series Explosion-proof Ammeters...

- ◆The enclosure of this explosion-proof ammeter/voltmeter is made of flame retardant plastic, temperature resistance and eco-friendly safety and extended product life.

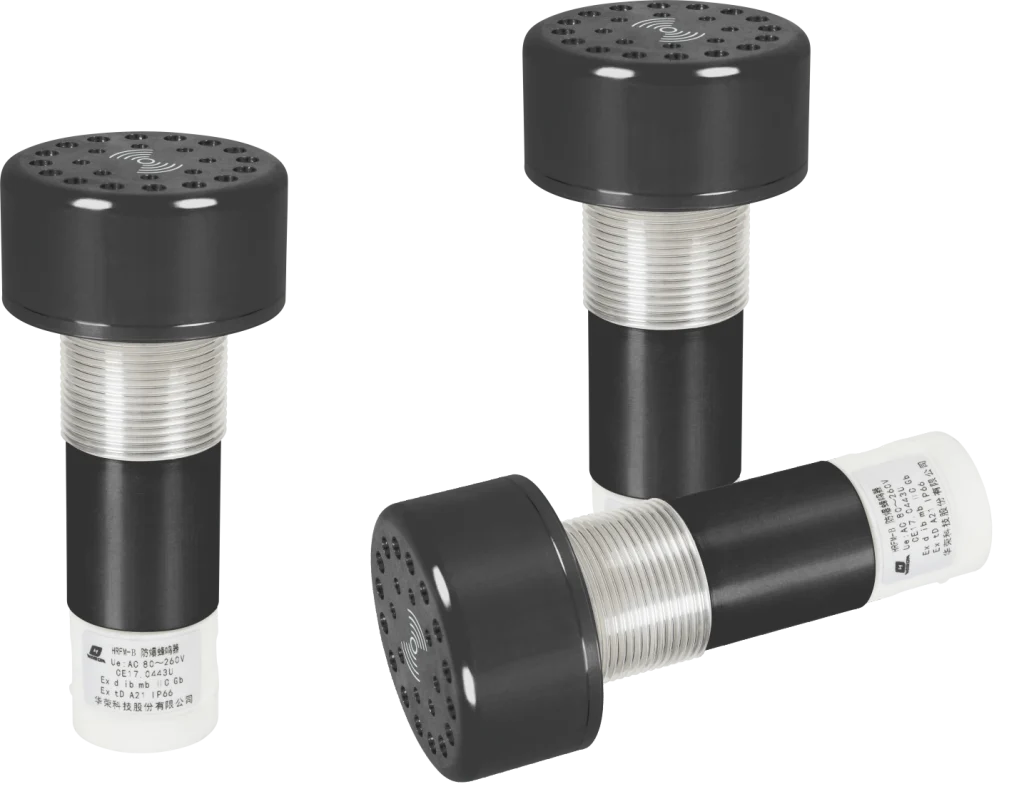

- ◆Excellent sealing between the glass window, cable entries, and the main body of the flameproof ammeter/voltmeter, it effectively blocks the ingress of dust, moisture, and explosive mixtures.

- ◆Utilizing an electromagnetic operating principle with a pointer display, the explosion-proof ammeters/voltmeters provides a simple, cost-effective solution and highly responsive feedback on parameter trends.

- ◆These explosion-proof analog ammeter /voltmeter endure the hard conditions, they guarantee continuous and reliable measurement of electrical parameters, delivering critical data for maintaining system safety and stability.

TECHNICAL DATA

Explosion Protection Type

Standards: CENELEC, IEC, NEC

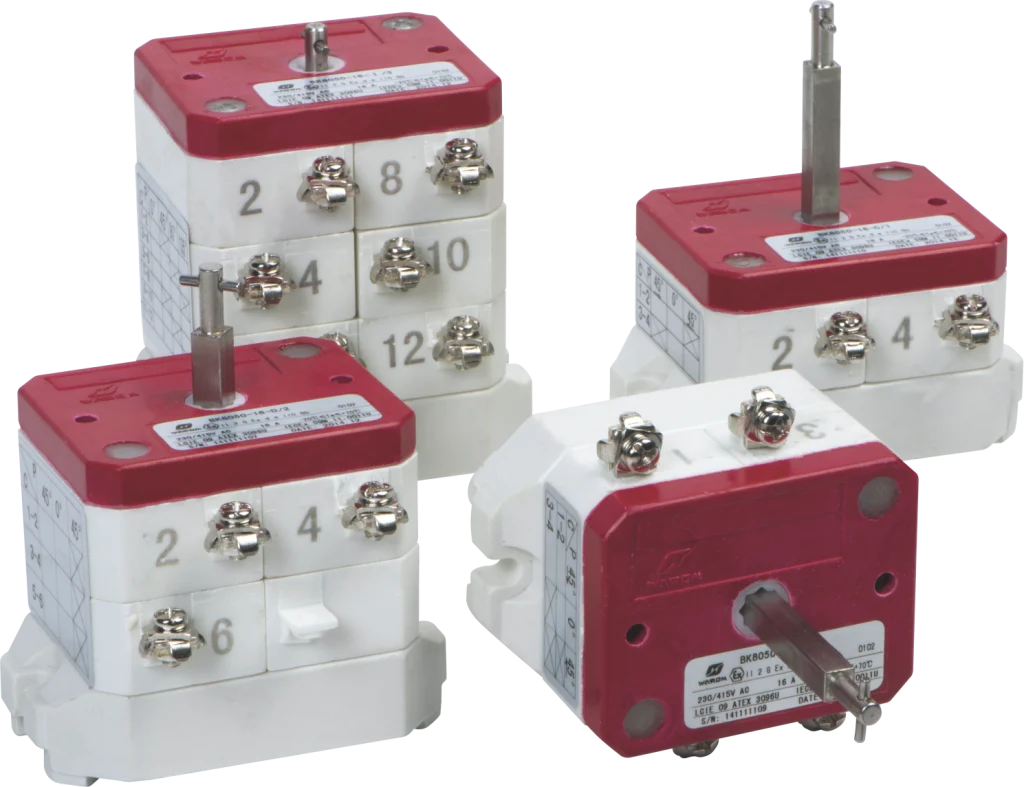

Zones: Zone 1 and Zone 2; Zone 21 and Zone 22; Class I, Zone 1 and Zone 2; Class I, Division 2, Groups A, B, C, D

Explosion Protection Ratings:

- Ammeter: IECEx(Gas): Ex eb IIC Gb; ATEX(Gas): II 2 G Ex eb IIC Gb

- Voltmeter: IECEx(Gas): Ex eb mb IIC Gb; ATEX(Gas): II 2 G Ex eb mb IIC Gb

Product Parameters

Material: Enclosure: Flame retardant plastic

Working mode: Electromagnetic type (moving iron)

Accuracy: Class 1.5

Service temperature: -60°C ~ +80°C

Cable connection: 2.5mm²

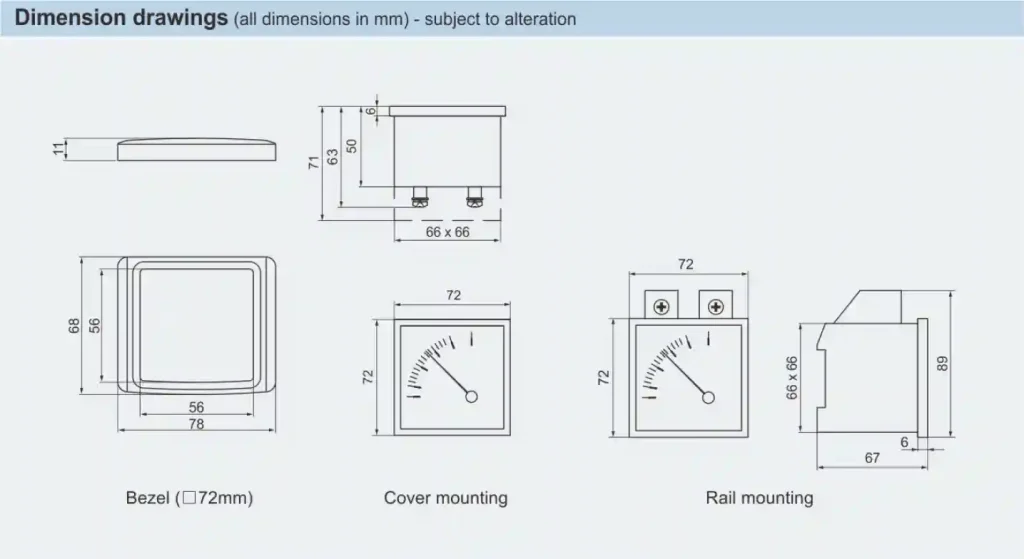

Size: 72x72mm

Product Classification & Origin

HS code: 903033

Country of origin: China

Applicable Industries

Heavy Industries: Petrochemical, natural gas, coal, metallurgy, military, nuclear power, aerospace, firefighting, pharmaceuticals, textiles, grain & oil, municipal services, public security, shipping, ports, railways and so on.

Function: Explosion-proof meters act as safe “power monitoring windows” that intuitively display vital electrical parameters.

Safety: They address risks from sparks caused by faulty gauges or loose connections, serving as essential “safety sentinels” in modern industrial safety systems.

Credibility

Certifications: Certified to ATEX, IECEx, EAC and more, meeting stringent global requirements.

Reliability: Engineered for safety in hazardous environments, delivering reliable performance even in damp, vibrating, and corrosive harsh environments.

FAQ

Q1: Can we use ordinary instruments in hazardous areas?

A1: No! Ordinary instruments, during normal operation or in the event of a fault, can generate electrical sparks or high surface temperatures sufficient to ignite surrounding flammable gases or dusts.

Q2: Is it mandatory to have explosion-proof certification (e.g., ATEX, IECEx)?

A2: Yes, it is typically mandatory. Equipment must possess corresponding regional certifications for sale and installation in different markets.

Q3: What are the key considerations for the daily maintenance of explosion-proof ammeters/voltmeters?

A3: Maintenance includes:

- Periodic Inspection: Check for mechanical damage, corrosion, or rust.

- Integrity of Fasteners: Regularly verify all fasteners (cover bolts, cable glands) are tightened.

- Cleaning: Use a damp cloth and non-corrosive cleaner to prevent dust accumulation; never clean with power on or cover open.

- Record Keeping: Maintain records of all maintenance and inspection activities.

Q4: Can we open explosion-proof instruments for repair or calibration ourselves?

A4: It is absolutely not recommended. Opening an explosion-proof enclosure must only be performed by specially trained personnel in a safe area. Unauthorized opening voids certification and introduces significant safety risks.