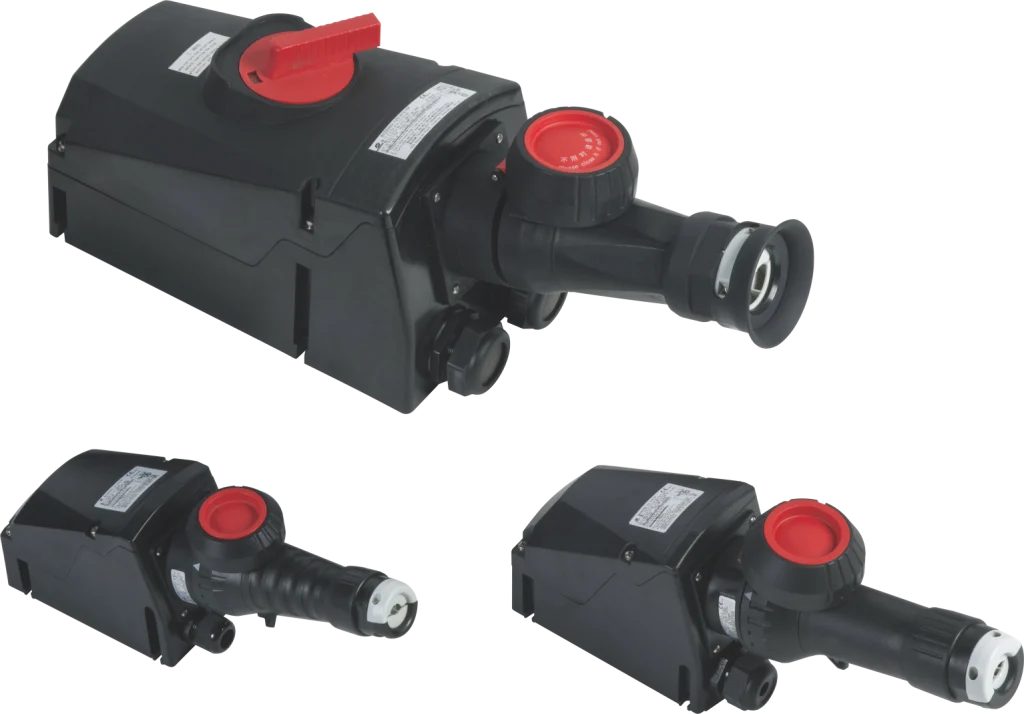

BCZ85 Series Explosion-proof Plugs...

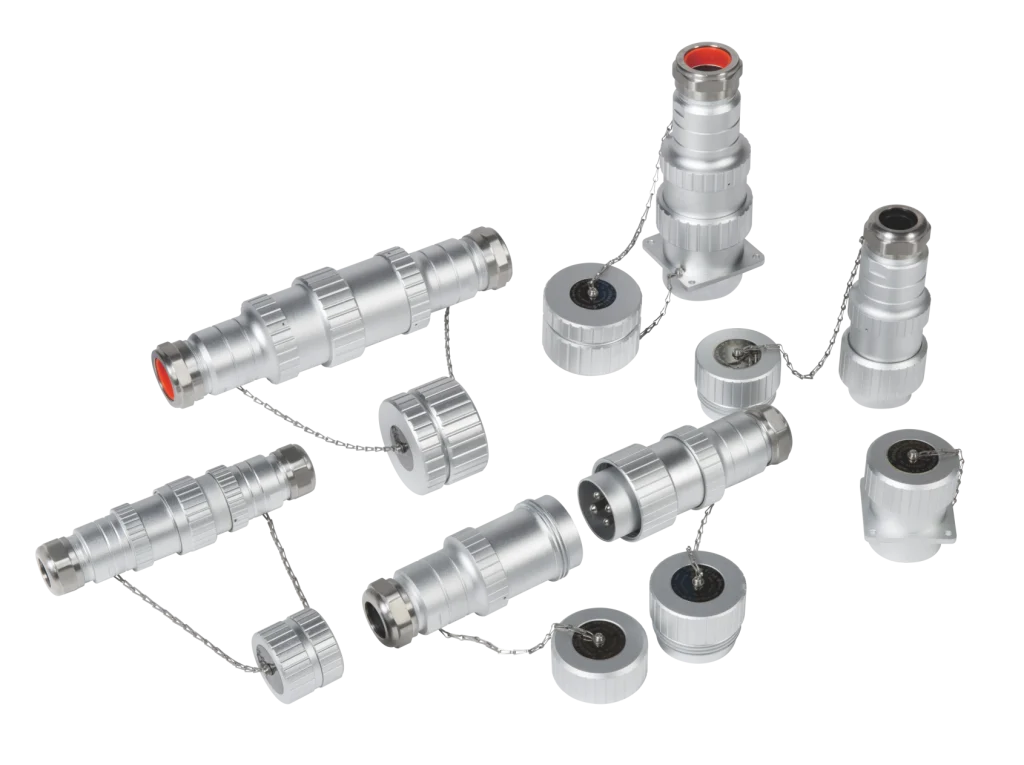

- ◆ This Explosion-proof Plugs And Sockets is made of high-performance composite material Copper-free Aluminium Alloy, which is high-strength and corrosion-resistant.

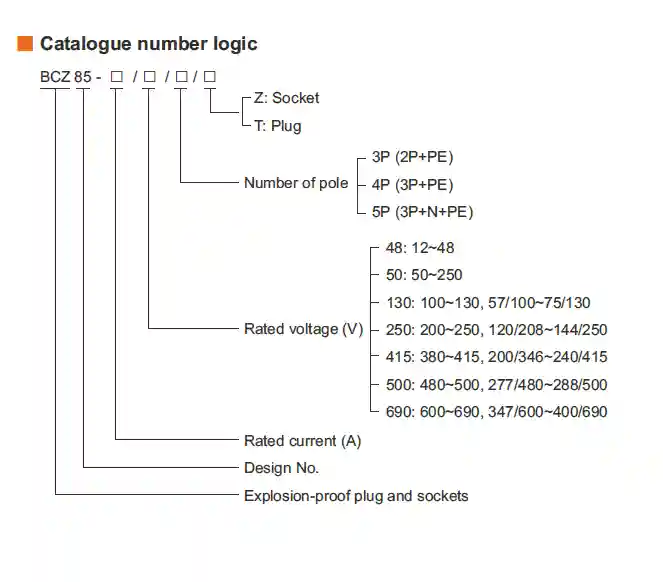

- ◆ Plugs are classified by the number of poles into 3P, 4P, and 5P.

- ◆The Flameproof Plugs and Sockets are quipped with interlocking switch, plug can only be pulled out after switching off; and can be switched after inserting the plug .

TECHNICAL DATA

Explosion Protection Type

- Standards: CENELEC, IEC, NEC.

- Zones: Zone 1 and Zone 2; Zone 21 and Zone 22; Class I, Zone 1 and Zone 2; Class I, Division 1, Groups A, B, C, D.

- Explosion Protection Ratings:

- IECEx (Gas and dust): Ex db IIC T6 Gb; Ex tb IIIC T80°C Db.

- ATEX (Gas and dust): II 2 G Ex db IIC T6 Gb; II 2 D Ex tb IIIC T80°C Db.

Product Parameters

- Product Type: BCZ85

- Certificates: IECEx; ATEX; CU-TR.

- Material:

- Enclosure: Copper-free Aluminium Alloy, powder coated surface.

- Exposed fastener: Stainless steel.

- Enclosure Color: Window grey (RAL7040).

- Electrical Data:

- Rated voltage: Max. 690V AC.

- Rated current: 100A, 125A.

- Protection:

- Degree of protection: IP66.

- Ambient temperature: -60°C ~ +58°C.

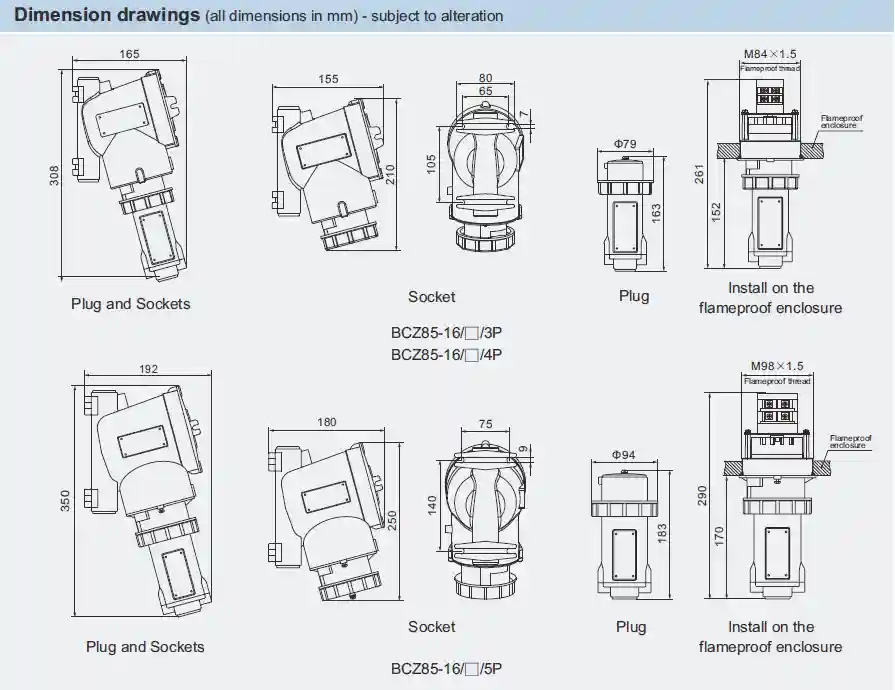

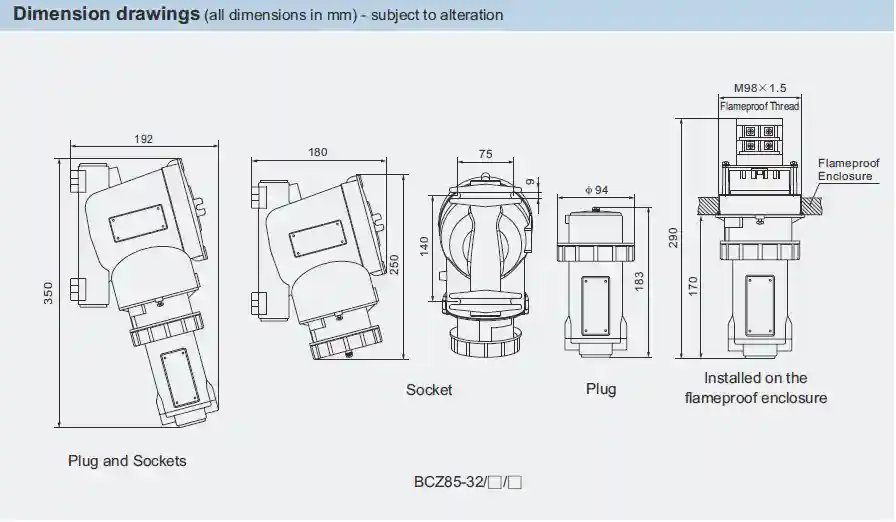

- Connection & Entries:

- Internal & external earthing: M6/M8.

- Cross section of cable: 10~16 $mm^{2}$.

- Cable entry of socket: 1 x M63 x 1.5.

- Cable entry of plug: 1 x M50 x 1.5.

- Cable Gland (Optional): DQM-II (Ex d) or DQM-III (Ex d) is recommended.

Product Classification & Origin

- HS code: 853690.

- Country of origin: China.

Applicable Industries

- Explosion-proof Plugs and Sockets are engineered for industries such as petrochemical, natural gas, coal, metallurgy, military, nuclear power, aerospace, and more.

- Utility: They offer standardized, convenient power interfaces for mobile equipment, eliminating complex temporary wiring.

- Safety Performance: As a cornerstone of industrial safety, these hazardous location connectors withstand harsh conditions while providing high ingress IP protection against dust and moisture.

Credibility

- Certifications: Warom’s hazardous location connectors are certified to ATEX, IECEx, and EAC standards.

- Reliability: These products deliver reliable performance even in damp, vibrating, or corrosive environments.

- Support: Warom offers a seamless, end-to-end service from initial design assessment to final certification and global logistics.

FAQ

- Q1: How to select the appropriate explosion-proof rating?

- A: Selection depends on area classification (e.g., Zones 1/21), explosive substance properties (gas groups/temperature classes), and environmental conditions (IP ratings).

- Q2: What is the relationship between IP ratings and explosion-proof ratings?

- A: They are independent but equally critical; IP ratings focus on preventing ingress of solids and water, while explosion-proof ratings ensure internal sparks cannot ignite the external atmosphere.

- Q3: What are the key precautions for installing explosion-proof connectors?

- A: Installation must be performed by qualified personnel, following guidelines for proper cable sealing with compatible glands and ensuring the enclosure is permanently and reliably grounded.