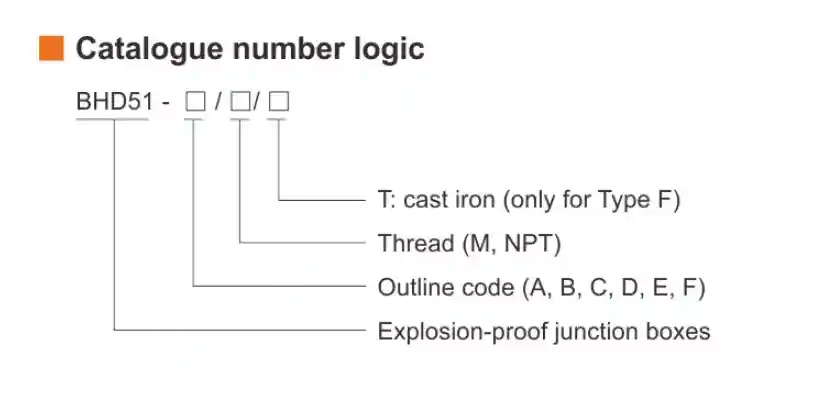

BHD51 Series Explosion-proof Junction...

- ◆ Constructed with a high-strength copper-free aluminum alloy, this explosion-proof junction boxes features robustness, corrosion resistance and a high protection level (IP66).

- ◆ The flameproof junction box treated with anti-static coating and all fasteners are anti-loosening.

- ◆ Use flameproof junction enclosure and sealed structure to contain and isolate any potential electric sparks or high-temperature faults that may occur at cable connections within the enclosure.

- ◆The IP66 rating prevents internal component of the ex junction boxes aging and corrosion, which extends system life and lowers maintenance costs.

TECHNICAL DATA

Explosion Protection Type

- Standards: CENELEC, IEC, NEC.

- Zones: Zone 1 and Zone 2; Zone 21 and Zone 22; Class I, Zone 1 and Zone 2; Class I, Division 1, Groups A, B, C, D.

- Explosion Protection Ratings:

- IECEx (Gas and dust): Ex db IIC T6 Gb; Ex tb IIIC T80°C Db.

- ATEX (Gas and dust): II 2 G Ex db IIC T6 Gb; II 2 D Ex tb IIIC T80°C Db.

Product Parameters

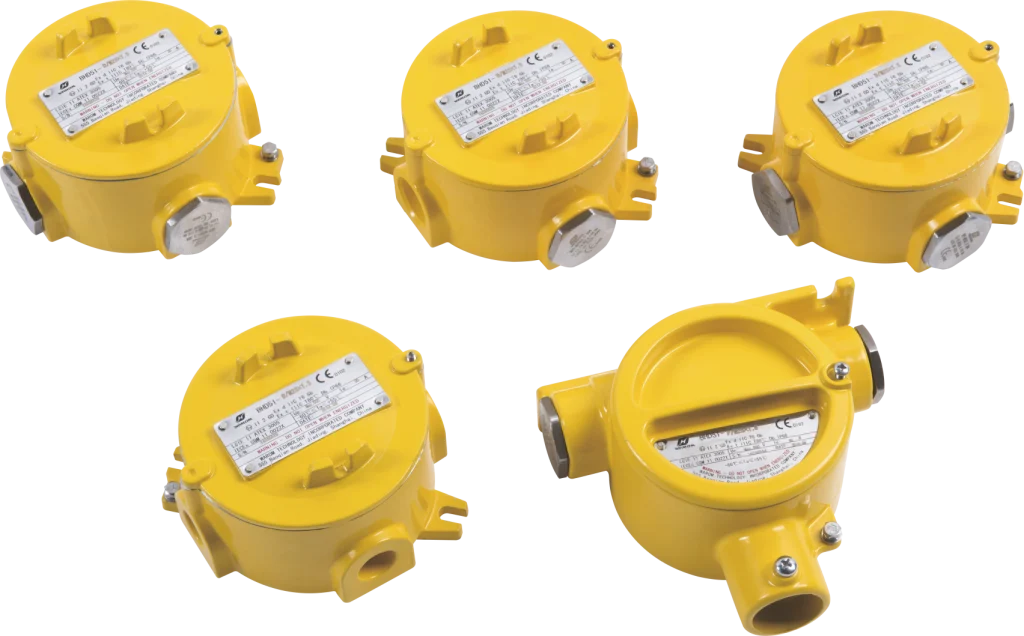

- Product Type: BHD51.

- Material:

- Enclosure: Copper-free Aluminium Alloy, powder coated surface.

- Exposed fastener: Stainless steel.

- Enclosure Color: Yellow (RAL1021).

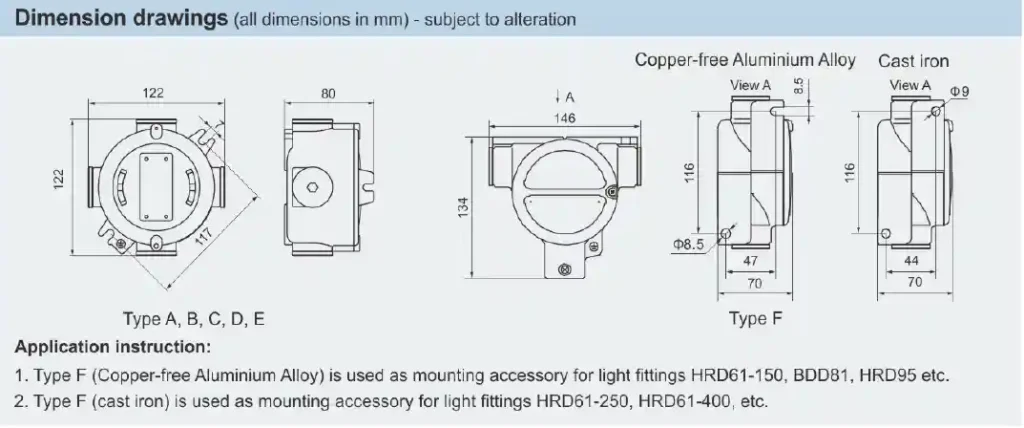

- Terminal Data: Number 6 terminals (Type A~E), 4 terminals (Type F); Cross section of cable 0.2-2.5mm².

- Electrical:

- Rated voltage: Max. 690V AC 50/60Hz; Max. 500V DC.

- Rated current: 20A.

- Protection:

- Degree of protection: IP66.

- Ambient temperature: -60°C ~ +60°C.

- Earthing: Internal & external earthing: M5.

- Cable Entries: Standard M☐ x 1.5 plugs; NPT☐ plugs on request.

- Cable Glands: Optional, DQM-II (Ex d) or DQM-III (Ex d) is recommended.

Product Classification & Origin

- HS Code: 853650.

- Country of Origin: China.

Applicable Industries

- Explosion-Proof Junction Boxes are engineered for hazardous environments including petrochemical, natural gas, coal, metallurgy, military, nuclear power, aerospace, firefighting, and more.

- Safety Role: They act as a critical link in modern industrial safety frameworks, providing physical isolation and energy control for electrical connections.

- Durability: Built with a robust explosion-proof structure to deliver long-lasting, corrosion-resistant performance in harsh conditions with high temperatures, heavy dust, and corrosive gases.

Credibility

- Certifications: Certified to ATEX, IECEx, EAC, and other stringent global standards.

- Performance: Features a T5~T6 temperature rating and IP66 protection.

- Support: Warom offers a seamless, end-to-end service from initial design assessment to final certification and global logistics.

FAQ

- Q1: What are the principles of explosion-proof junction boxes?

- A: They are based on two main types: Flameproof (Ex d), which uses precision gaps to cool flames, and Increased Safety (Ex e), which prevents arcs and sparks through enhanced insulation.

- Q2: Are the terminal boxes in need of regular maintenance?

- A: Yes; critical checks include inspecting flameproof surfaces for damage, ensuring tight fasteners, and replacing damaged parts with original factory spare parts to restore protection grades.

- Q3: Can internal wiring be conducted carelessly after installing the ex-terminal boxes?

- A: Absolutely not; the box only provides “containment,” and internal electrical connections must strictly comply with electrical standards and other equipment must also be explosion-proof.

- Q4: Is it fully waterproof/dustproof?

- A: This depends on the IP rating; typical hazardous location junction boxes (IP66/67) resist powerful water jets or temporary immersion.

RESOURCE DOWNLOAD

RELATED PRODUCTS

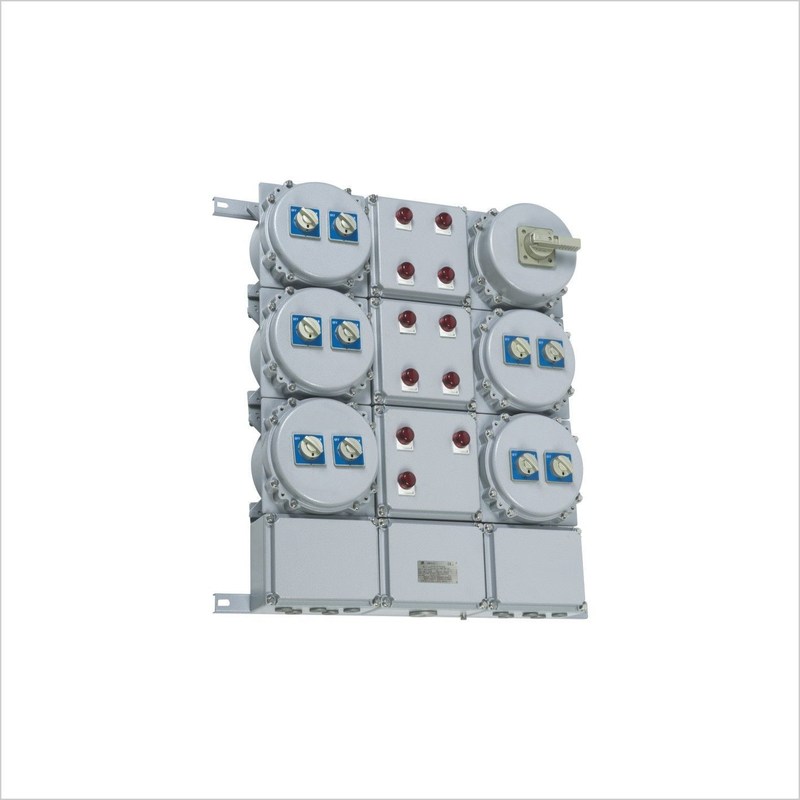

BXT8050 Series Explosion-proof Enclosures

Explosion Protection Type Stan...

BXM(D)53 Series Explosion Proof Illumination Distribution Boxes (Ex D E IIC) IP66

Explosion Protection Type Stan...

BXM(D)8050 Series Explosion Proof Lighting Distribution Boxes Surface Mounting

Explosion Protection Type Stan...

BXM(D)8061 Series Illumination Distribution Box Explosion Proof Stainless Steel

Explosion Protection Type Stan...