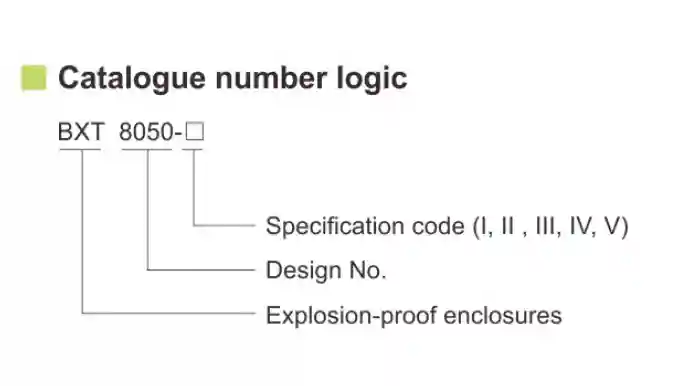

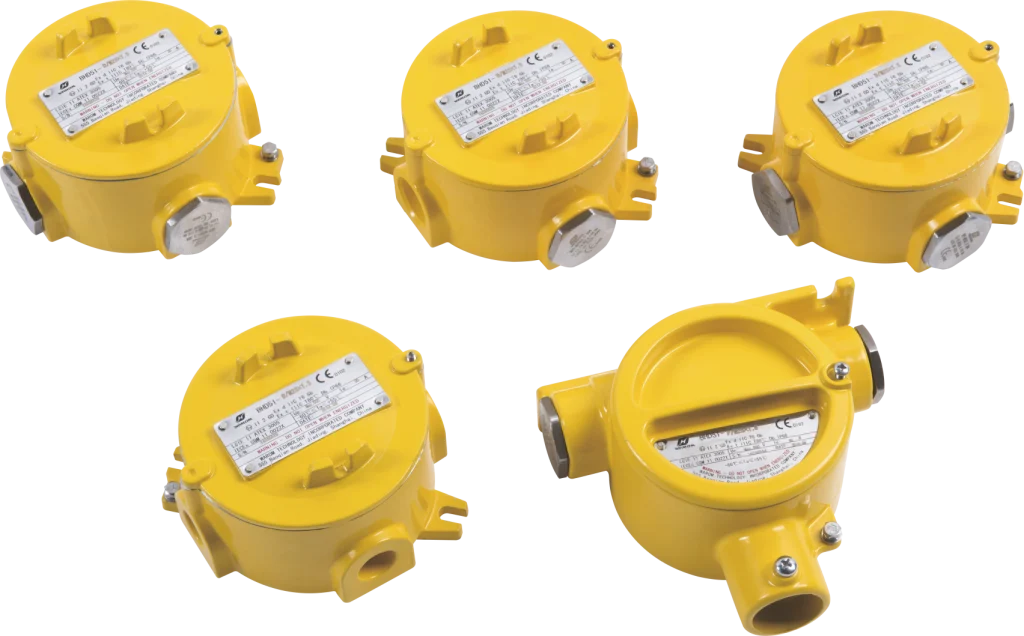

BXT8050 Series Explosion-proof Enclosures

- ◆ The explosion-proof enclosure is an increased-safety enclosure (Ex e) made of GRP, available in 5 versions.

- ◆ This explosion-proof enclosure allows cable entries to be drilled and components to be installed by the user on request.

- ◆ This explosion-proof enclosure requires that safety shall be considered when installing components in accordance with relevant electrical standards.

TECHNICAL DATA

Explosion Protection Type

Standards: CENELEC, IEC, NEC

Zones:

- Zone 1 and Zone 2

- Zone 21 and Zone 22

- Class I, Zone 1 and Zone 2

- Class I, Division 1, Groups C, D (for BXT series)

- Class I, Division 2, Groups A, B, C, D (for BXT8050)

Explosion Protection Ratings:

- IECEx (Gas and dust): Ex db IIB+H2 Gb; Ex tb IIIC Db IP66

- ATEX (Gas and dust):

- II 2 G Ex db IIB+H2 Gb

- II 2 D Ex tb IIIC Db IP66

- II 2 G Ex e II (for BXT8050)

Product Parameters

BXT8050

Material:

- Enclosure: Copper-free Aluminium Alloy, powder coated surface or GRP (glass fibre-reinforced polyester resin)

- Exposed fastener: Stainless steel

Enclosure Color: Window grey (RAL7040) (for BXT series)

Internal & External Earthing: * BXT series: M6/M6 or M6/M8 or M8/M8 depending on model size

Degree of Protection: IP66 or IP54

Ambient Temperature: -60°C ~ +200°C or -20°C ~ +60°C

Mounting feet: Carbon steel, powder coated surface

Product Classification & Origin

HS code: 732690

Country of Origin: China

Applicable Industries

An explosion-proof empty enclosure is a specialized housing designed for hazardous environments where explosive gases or dust are present—such as petroleum, chemical, pharmaceutical, and military industries. It is a fundamental explosion-proof enclosure supplied without any pre-installed electrical components, providing only a protected and isolated space. Its primary function is to ensure safe connection, branch wiring, and transition protection for cables and conductors routed through hazardous areas. It effectively isolates any sparks or high temperatures generated at cable joints from the external explosive atmosphere, serving as an indispensable “safety bridge” in a complete explosion-proof electrical system. Like certified explosion-proof equipment, the flameproof empty enclosure is constructed from high-strength materials, offering resistance to impact, corrosion, water, and dust.

Credibility

Electrical equipment for hazardous areas faces strict global mandates. The Certified Explosion-Proof Enclosure has obtained qualification certificates such as ATEX, IECEx, or EAC certification from an authorized body, specifying its protection type, gas group, and temperature class—serving as the essential safety guarantee and the authoritative pass for market entry.

FAQ

Q1: What is an explosion-proof empty enclosure? What’s the difference between it and a finished explosion-proof distribution box?

A1: An explosion-proof empty enclosure is a pre-certified basic housing supplied without any internal electrical components; it’s a semi-finished product. In contrast, a complete explosion-proof assembly is a fully assembled terminal device ready for direct use.

Q2: Can standard (non-certified) components be used inside a certified empty enclosure?

A2: Even with a certified explosion-proof enclosure, all internal electrical components must themselves be certified and comply with the explosion-protection standards required for the target hazardous environment.

Q3: Does self-assembly using an empty enclosure affect the overall explosion-proof certification?

A3: Yes, critically. The empty enclosure itself and every internal component installed must each hold valid and applicable explosion-proof certificates. Furthermore, assembly must be performed by qualified personnel in strict accordance with the installation instructions.

Q4: Why is an empty enclosure solution sometimes more cost-effective than purchasing a pre-built assembly?

A4: Advantages lie in flexibility, cost control, and lead time. It allows for flexible internal configuration based on actual needs. Standardized empty enclosures help reduce overall project costs and procurement of components can often be significantly faster than ordering custom pre-built assemblies.

RESOURCE DOWNLOAD

RELATED PRODUCTS

BHD51 Series Explosion-proof Junction Boxes

Explosion Protection Type Stan...

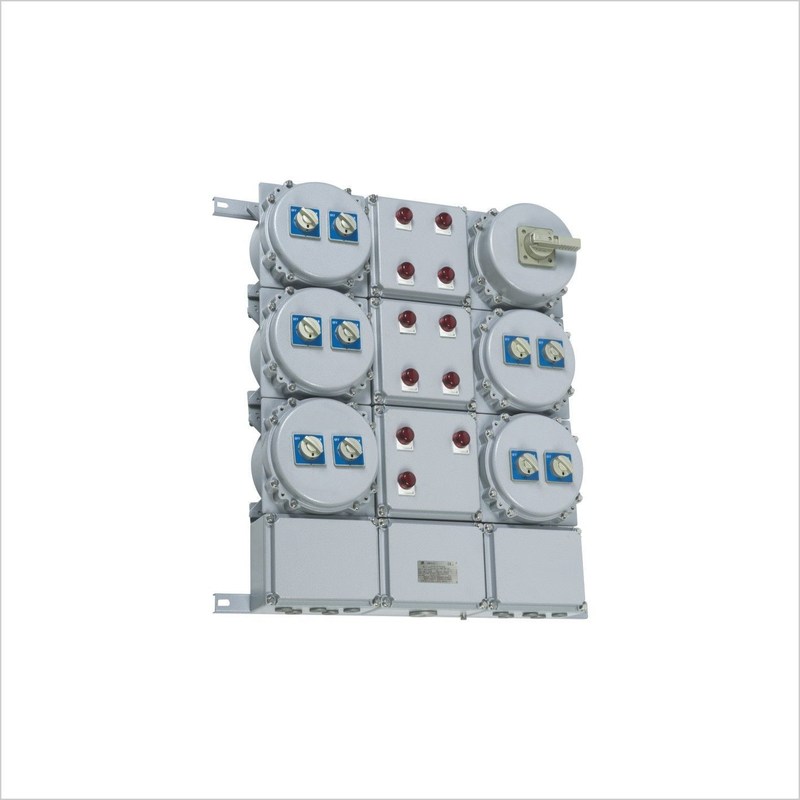

BXM(D)53 Series Explosion Proof Illumination Distribution Boxes (Ex D E IIC) IP66

Explosion Protection Type Stan...

BXM(D)8050 Series Explosion Proof Lighting Distribution Boxes Surface Mounting

Explosion Protection Type Stan...

BXM(D)8061 Series Illumination Distribution Box Explosion Proof Stainless Steel

Explosion Protection Type Stan...