BZC-HMl Series Explosion-proof Touchscreen

- ◆ This explosion-proof control stations are made of Copper-free Aluminium Alloy, can ensure safety by containing internal explosions and isolating the external hazardous atmosphere.

- ◆ The explosion proof enclosures treated with anti-static coating and all fasteners are anti-loosening.

- ◆The layout of buttons, switches, and other componentson of the explosion-proof control panel is rational and straightforward,ensuring ease of use and quick mastery.

- ◆The control methods of ex control station can be selected based on actual needs, such as manual control, automatic control, or remote control, catering to varying application scenarios.

TECHNICAL DATA

Explosion Protection Type

- Standards: CENELEC, IEC, NEC

- Zones:

- Zone 2

- Zone 21 and Zone 22

- Class I, Zone 2

- Class I, Division 2, Groups A, B, C, D

- Explosion Protection Ratings (Examples):

- IECEx (Gas and dust): Ex db eb nA IIC T6 Gc; Ex tb IIIC T80°C Db

- ATEX (Gas and dust): II 3 G Ex db eb nA IIC T6 Gc; II 2 D Ex tb IIIC T80°C Db

Product Parameters

- Material:

- Enclosure: Stainless steel

- Exposed Fastener: Stainless steel

- Enclosure Color: Metal colour

- Degree of Protection: IP65

- Ambient Temperature: 0°C ~ +50°C

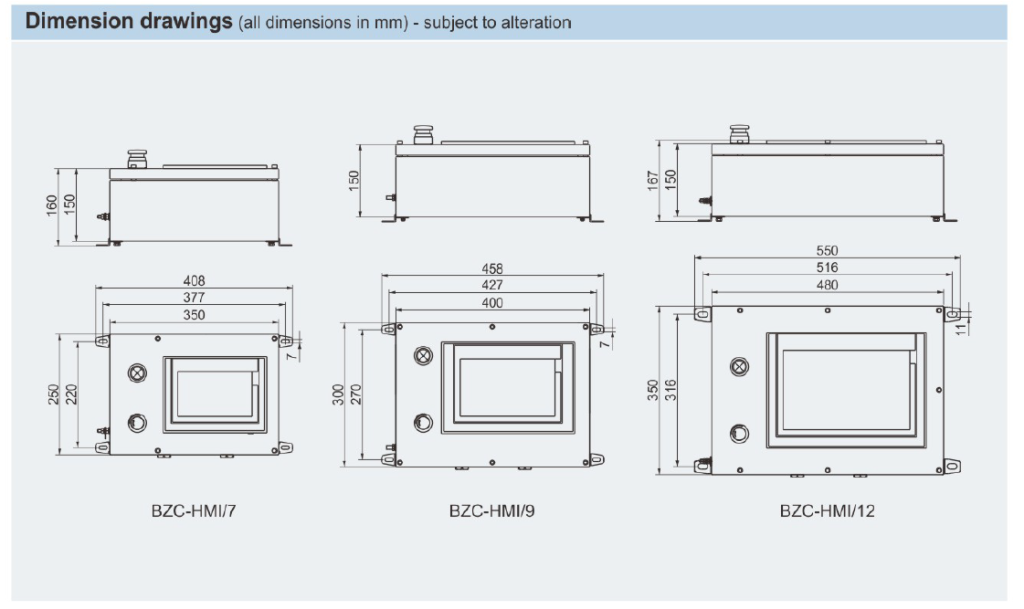

- Screen Size: 7.0 inches (800×480); 9.0 inches (800×480); 12.1 inches (1280×800)

- Rated Voltage: 24V DC

- Internal & External Earthing: M6/M6

- Cable Entries & Glands:

- Glands: DQM-I (Ex e) is recommended

- Mounting: Surface type

Product Classification & Origin

- HS code: 853710

- Country of Origin: China

Applicable Industries

- Heavy Industries: Oil and gas, petrochemical, coal, metallurgy, military, nuclear power, aerospace, marine, and more.

- Function: Features a multi-position, multi-contact design for complex command sequences (e.g., forward-reverse-speed change-stop).

- Safety: Certified flameproof design ensures it will not become an ignition source, guaranteeing safety in hazardous areas.

Credibility

- Certifications: Certified to ATEX, IECEx, EAC, and others.

- Reliability: Engineered for safety in hazardous environments, ensuring production continuity and the protection of personnel.

FAQ

- Q1: What does “Explosion-proof” mean for an explosion-proof control station?

- A1: It signifies the device’s ability to prevent the ignition of a surrounding explosive atmosphere through specialized construction that contains internal sparks or limits energy levels.

- Q2: In which industries are explosion-proof operator stations primarily used?

- A2: They are widely used wherever flammable gases, vapors, or dusts are present, such as Oil & Gas, Chemical & Pharmaceutical, Food Processing, and Marine industries.

- Q3: Can we open the operator station ourselves for maintenance or component replacement?

- A3: No! Only specially trained and authorized personnel may open the Ex control stations, and only in a confirmed safe area to avoid serious safety risks.

RESOURCE DOWNLOAD

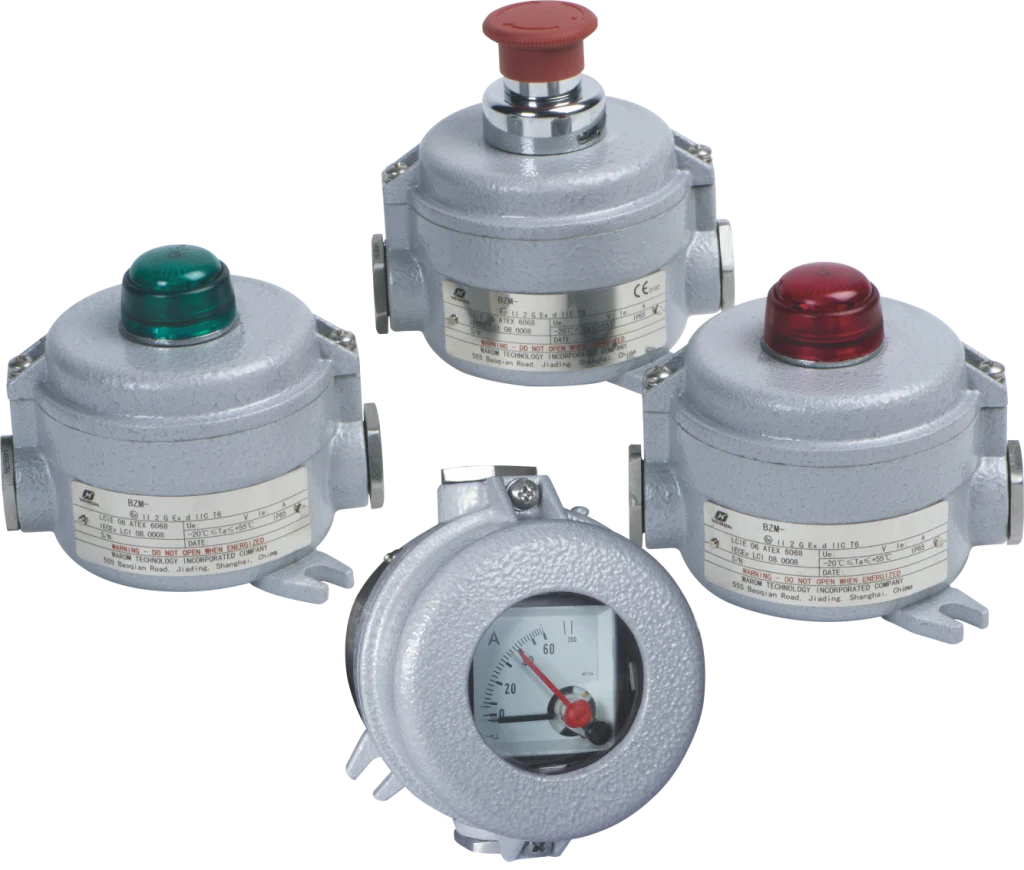

RELATED PRODUCTS

BZC8050 Series Control Stations (GRP)

Explosion Protection Type Stan...

BZC8050 Series Control Stations (Stainless Steel)

Explosion Protection Type Stan...

BZC8050 Series Control Stations (Copper-free Aluminium Alloy)

Explosion Protection Type Stan...

BZA85 Series Explosion-proof Control Unit Systems

Explosion Protection Type Stan...