DQM-CF Series Cable Gland...

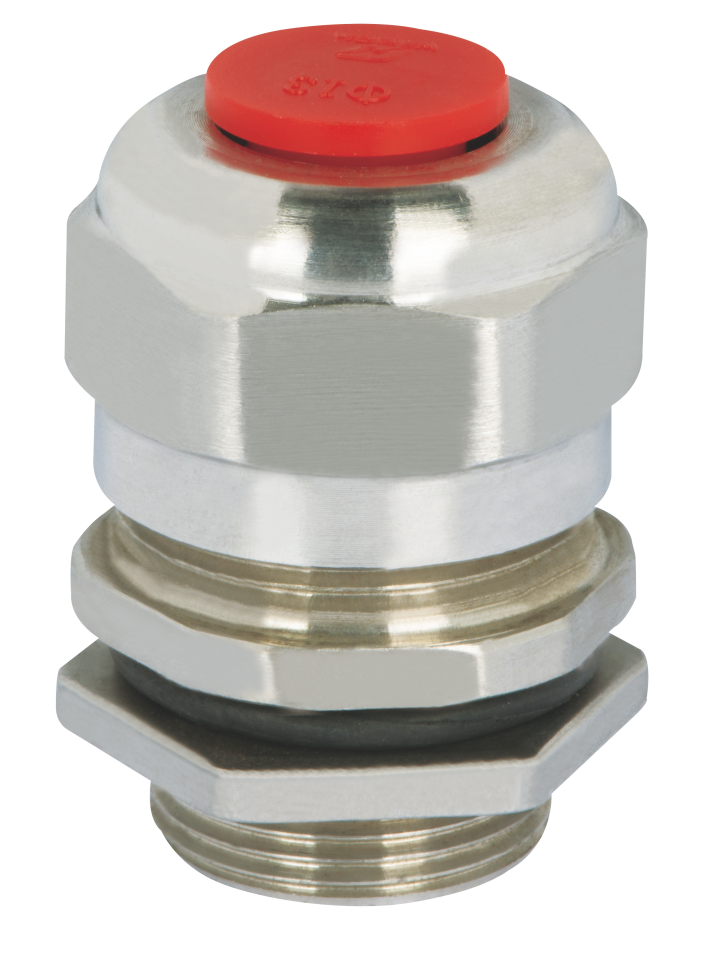

- ◆ Explosion-proof Cable Glands feature an Ex d, Ex e structure and are available in stainless steel or nickel plated brass.

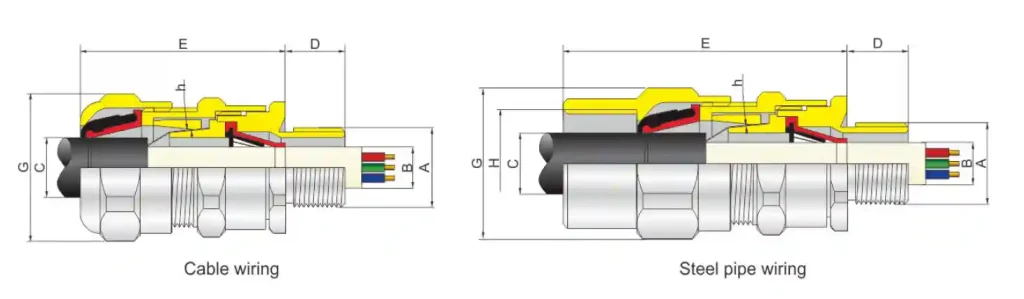

- ◆These explosion-proof cable glands adopt a Dual seal, suitable for both armored and unarmored cable.

- ◆The explosion-proof cable gland Complies with international explosion-proof standards, ensuring safe operation in hazardous areas.

- ◆For particular use with: cables that exhibit “cold flow” characteristics.

TECHNICAL DATA

Explosion Protection Type

Standards: CENELEC, IEC, NEC

Zones:

- Zone 1 and Zone 2

- Zone 21 and Zone 22

- Class I, Zone 1 and Zone 2

- Class I, Division 1, Groups B, C, D

Explosion Protection Ratings:

IECEX(Gas and dust): Ex db IIC Gb (only for M and NPT thread)

Ex eb IIC Gb

Ex tb IIIC Db

ATEX(Gas and dust): II 2 G Ex db IIC Gb (only for M and NPT thread)

II 2 G Ex eb IIC Gb

II 2 D Ex tb IIIC Db

Product Parameters

Material:

- Enclosure: 304 stainless steel, 316L stainless steel, or Q235

- Exposed fastener: Stainless steel

Rated Voltage: Max. 1000V AC 50/60Hz; Max. 1500V DC

Rated Current: Max. 1000A

Cable Entries: Standard M x 1.5 plug (size processed according to actual requirements), NPT plug on request

Cable Glands: DQM-II (Ex d) or DQM-III (Ex d) is recommended

Entry Direction: Bottom

Mounting:

- Surface type (standard)

- Pedestal type (optional)

Product Classification & Origin

HS code: 853710

Country of Origin: China

Applicable Industries

Modular Explosion-Proof Distribution Panels are specialized electrical apparatus designed for hazardous environments—such as those in the petroleum, chemical, pharmaceutical, and defense industries—where explosive gases or dust may be present. Their primary function is to safely distribute, control, and protect electrical power for area lighting systems, motors, and other equipment. Rather than merely preventing spark generation, these panels employ composite explosion-proof technologies combined with rugged mechanical construction to physically isolate potential internal arcs, sparks, or high temperatures from the external explosive atmosphere, thereby preventing the electrical equipment from becoming an ignition source.

A well-designed compartmentalized layout of explosion-proof lighting (power) distribution boxes, clear identification, and ample wiring space reduce troubleshooting time and maintenance risks, significantly lowering the total cost of ownership over the equipment’s lifecycle.

Credibility

Distribution Panels for Hazardous Locations are engineered for safety in hazardous environments. Certified to ATEX, IECEx, EAC and so on… they meet stringent global requirements. It functions not just as a protective firewall for personnel and the environment, but also as a stabilizer for continuous production. These certifications constitute authoritative validation of the product’s safety and reliability, forming a critical gateway to market compliance and acceptance.

CTA

For more detailed information on our explosion-proof illumination distribution boxes, customized solutions, or to request a quote, please do not hesitate to contact us. We are committed to providing you with professional lighting solutions and comprehensive technical service support.

FAQ

Q1: How do I choose the right explosion-proof distribution panels for my environment?

A: Match the panel to your site’s hazard level by checking two key ratings:

- Explosion-Proof Marking (Ex ___): Defines the protection method.

- IP Rating: Defines protection against dust and water.Also consider: Construction material, required circuit count, and modularity for future flexibility.

Q2: What do the labels and certifications on the modular explosion-Proof distribution panels mean?

A: Certifications are your guarantee of safety and compliance:

- Global Acceptance: Look for IECEx or ATEX marks for international projects.

- Vital Specifications: Always cross-check the Ex marking, IP code, voltage/current ratings, and manufacturer details against your requirements.

Q3: Why are distribution panels for hazardous locations more expensive?

A: The premium reflects superior safety engineering and compliance costs:

- Robust Materials: Heavy-duty housings and specialized components.

- Rigorous Testing: Each design passes extreme prototype tests.

- Mandatory Certifications: Global approvals require significant investment.

RESOURCE DOWNLOAD

RELATED PRODUCTS

DQM-III&II Explosion-proof Cable Glamds (Armored compound Barrier)

Explosion Protection Type Stan...

DQM-III&I Explosion-proof Cable Glamds (Unarmird compound Barrier)

Explosion Protection Type Stan...

DQM-I Series Explosion-proof Cable Glands (Metal unarmored)

Explosion Protection Type Stan...

BGJ Series Metal Explosion Proof Cable Connectors CENELEC IEC Standards

Explosion Protection Type Stan...