DQM-I Series Explosion Proof...

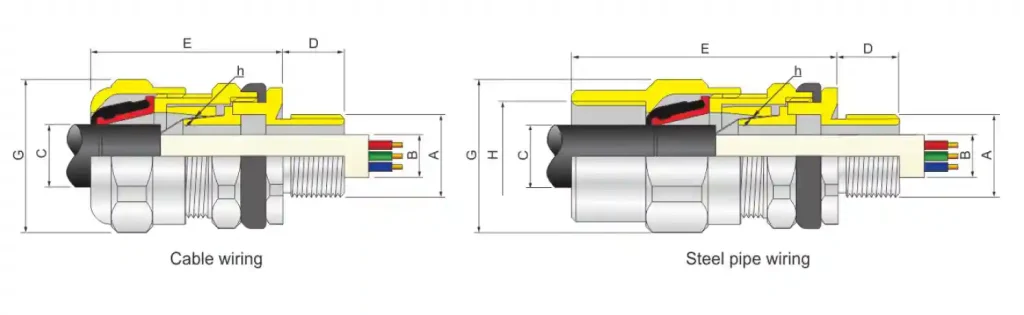

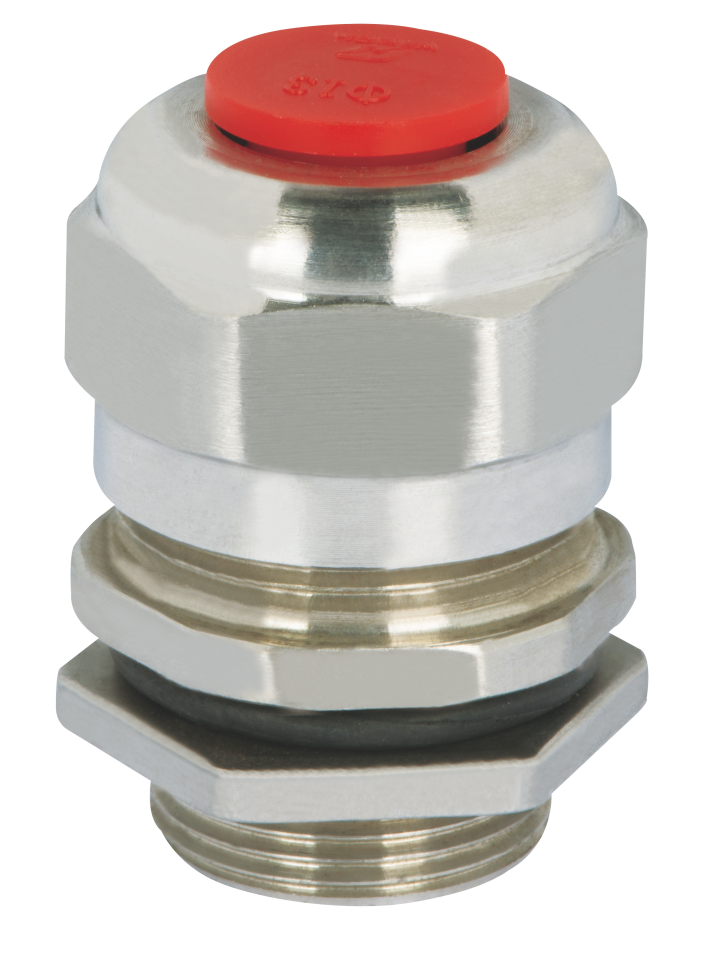

- ◆ Explosion-proof Cable Glands feature an Ex d, Ex e structure and are available in stainless steel or nickel plated brass.

- ◆These explosion-proof cable glands adopt a Dual seal, suitable for both armored and unarmored cable.

- ◆The explosion-proof cable gland Complies with international explosion-proof standards, ensuring safe operation in hazardous areas.

- ◆For particular use with: cables that exhibit “cold flow” characteristics.

TECHNICAL DATA

Explosion Protection Type

Standards: CENELEC, IEC, NEC

Zones:

- Zone 1 and Zone 2

- Class I, Zone 1 and Zone 2

- Class I, Division 2, Groups A, B, C, D

Explosion Protection Ratings:

- IECEx (Gas): Ex eb mb IIC Gb

- ATEX (Gas): II 2 G Ex eb mb IIC Gb

Product Parameters

Material:

- Enclosure: PC

Rated Voltage: MAX. 500V AC/DC 50/60Hz

Rated Current: 0.5A, 0.63A, 0.8A, 1A, 1.25A, 1.6A, 2A, 2.5A, 3.15A, 4A, 5A, 6.3A, 8A, 10A, 12.5A, 16A

Ambient Temperature: -60°C ~ +100°C

Product Classification & Origin

HS code: 853710

Country of Origin: China

Applicable Industries

Explosion proof fuses are core protective components for electrical systems in hazardous environments, designed to prevent fire and explosion risks caused by electrical faults. They are widely applied in oil & gas (drilling platforms, refineries), mining (underground coal/metal mines), chemical & pharmaceutical (reactors, mixing equipment), and marine & offshore engineering (ship engine rooms, offshore platforms). These components quickly cut off overcurrent or short-circuit current, and their robust explosion-proof enclosures contain internal arcs and flames. Ideal for harsh conditions like high temperature, corrosion, and humidity, these fuses ensure safe, stable operations across high-risk industries.

Credibility

Explosion Proof Fuses for Hazardous Locations are engineered for safety in hazardous environments. Certified to ATEX, IECEx and so on… they meet stringent global requirements. It functions not just as a protective firewall for personnel and the environment, but also as a stabilizer for continuous production. These certifications constitute authoritative validation of the product’s safety and reliability, forming a critical gateway to market compliance and acceptance.

CTA

For more detailed information on our explosion-proof distribution boxes and explosion proof fuses, customized solutions, or to request a quote, please do not hesitate to contact us. We are committed to providing you with professional solutions and comprehensive technical service support.

FAQ

Q1: What is the core function of explosion proof fuses?

A: Explosion proof fuses are specialized protective components for electrical systems in hazardous environments. They quickly cut off overcurrent or short-circuit current, and their robust explosion-proof enclosures contain internal arcs and flames, preventing fires or explosions triggered by electrical faults.

Q2: What is the difference between explosion proof fuses and regular fuses?

A: Unlike regular fuses that only provide overcurrent protection, explosion proof fuses have a sealed explosion-proof enclosure. This structure can contain any arc or flame generated when the fuse blows, avoiding ignition of flammable gases, vapors or dust in the surrounding hazardous atmosphere.

Q3: How to select the right explosion proof fuse for my equipment?

A: Selection should be based on three key factors: the rated voltage and current of your electrical system, the type of hazardous environment (e.g., flammable gas vs. combustible dust), and the working conditions (temperature, humidity, corrosion level) of the application site.

RESOURCE DOWNLOAD

RELATED PRODUCTS

DQM-III&II Explosion-proof Cable Glamds (Armored compound Barrier)

Explosion Protection Type Stan...

DQM-III&I Explosion-proof Cable Glamds (Unarmird compound Barrier)

Explosion Protection Type Stan...

DQM-I Series Explosion-proof Cable Glands (Metal unarmored)

Explosion Protection Type Stan...

BGJ Series Metal Explosion Proof Cable Connectors CENELEC IEC Standards

Explosion Protection Type Stan...