HRZX91 Series Explosion-proof Position...

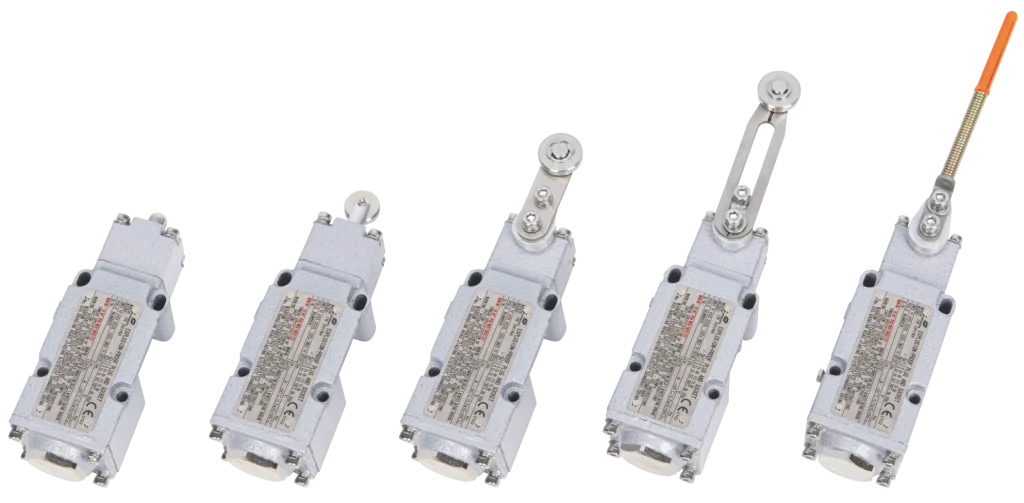

- ◆ This explosion-proof position switches are made of high-quality aluminum ingots from large state-owned enterprises。

- ◆ The surface of the shell is shot-blasted and then treated with high-pressure electrostatic powder coating.

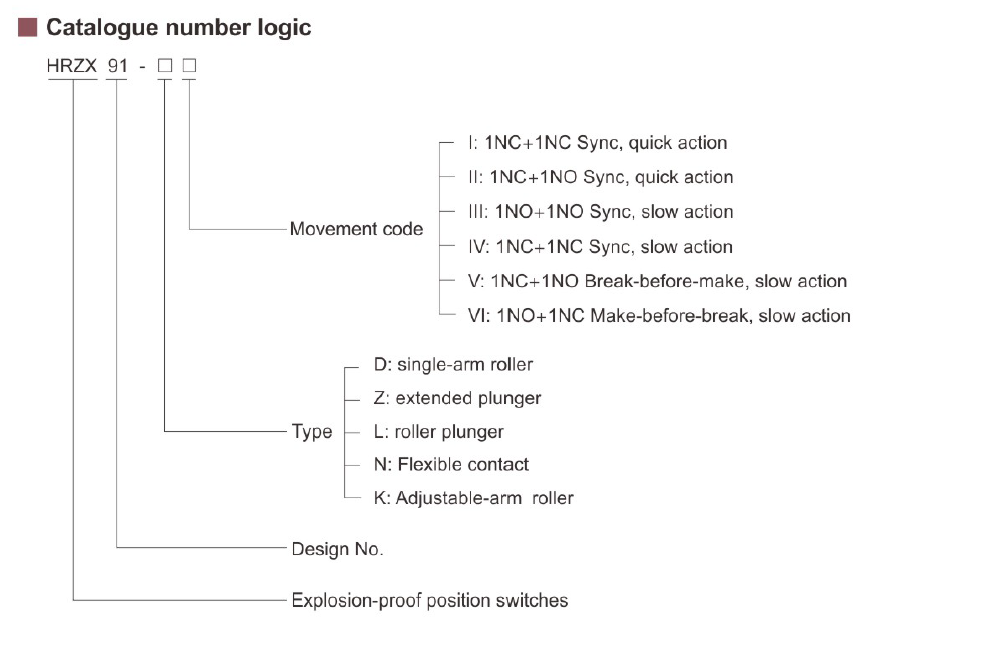

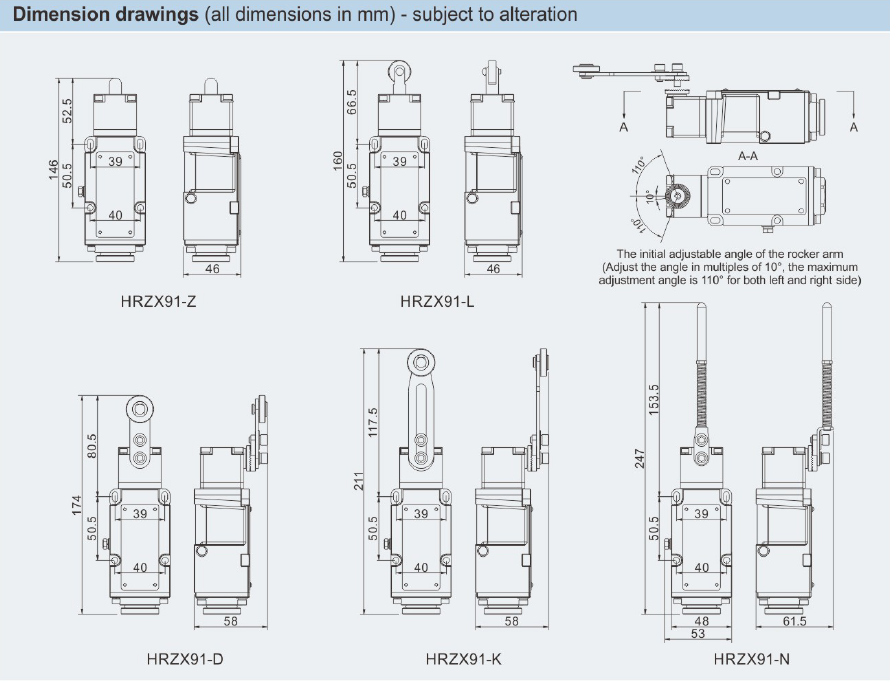

- ◆There are various types of functional movements and travel heads available, and they can be combined in any way.

- ◆Fully explosion-proof products, with excellent explosion-proof performance

- ◆Professional design of sealing structure, high-temperature resistant sealing material, anti-aging property.

TECHNICAL DATA

Explosion Protection Type

- Standards: CENELEC, IEC, NEC.

- Zones: Zone 1 and Zone 2; Zone 21 and Zone 22.

- Explosion Protection Ratings:

- IECEx (Gas and dust): Ex db IIC T6 Gb; Ex tb IIIC T80°C Db.

- ATEX (Gas and dust): II 2 G Ex db IIC T6 Gb; II 2 D Ex tb IIIC T80°C Db.

Product Parameters

- Product Type: HRZX91.

- Material:

- Enclosure: Copper-free Aluminium Alloy, powder coated surface.

- Exposed fastener: Stainless steel.

- Enclosure Color: Window grey (RAL7040).

- Electrical Data:

- Rated voltage: Max. 380V AC 50/60Hz, 250V DC.

- Rated current: 3A AC / 0.27A DC.

- Protection:

- Degree of protection: IP66.

- Ambient temperature: -60°C ~ +60°C.

- Connection & Entries:

- Internal & external earthing: M4 / M4.

- Cable entries: 1 x M20 x 1.5.

- Cable glands: Optional; DQM-II (Ex d) or DQM-III (Ex d) is recommended.

Product Classification & Origin

- HS code: 853710.

- Country of origin: China.

Applicable Industries

- Engineered for: Industries such as oil and gas, petrochemical, coal, metallurgy, military, nuclear power, aerospace, firefighting, pharmaceuticals, textiles, grain & oil, municipal services, public security, shipping, ports, railways, and more.

- Utility: This explosion-proof control panel features a multi-position, multi-contact design, enabling complex command sequences (such as forward-reverse-speed change-stop) for on-site equipment.

- Safety Performance: Certified flameproof design ensures it will not become an ignition source, making it perfectly suited for harsh industrial environments where flammable elements are a constant threat.

Credibility

- Certifications: Warom’s hazardous area control stations are certified to ATEX, IECEx, EAC, and other stringent global requirements.

- Reliability: These products serve as a reliable partner in ensuring production continuity and as a “safety guardian” for personnel and the environment.

- Support: Committed to providing professional lighting solutions and comprehensive technical service support, including customized solutions.

FAQ

- Q1: What does “Explosion-proof” mean for an explosion-proof control station?

- A: It signifies the device’s ability to prevent the ignition of a surrounding explosive atmosphere through specialized construction that contains internal sparks or limits energy levels.

- Q2: In which industries are explosion-proof operator stations primarily used?

- A: They are widely used in any environment with flammable gases, vapors, or dusts, such as oil & gas platforms, refineries, chemical plants, and food processing facilities.

- Q3: Can we open the operator station ourselves for maintenance or component replacement?

- A: No. Only specially trained and authorized personnel may open Ex control stations, and only in a confirmed safe area, to avoid compromising explosion-proof integrity.