Hazardous industrial work leaves no room for guesswork, and lighting often decides whether a task feels controlled or risky. We’ve seen standard fixtures falter in these zones, so our focus is on specialized local caution spotlights that pair precise illumination with active warnings to protect people and keep operations steady.

Critical Challenges in Hazardous Industrial Illumination

Operating in hazardous industrial environments presents significant challenges, particularly concerning illumination and safety. Areas with flammable gases, vapors, or combustible dust require specialized lighting to prevent ignition, which standard fixtures cannot provide. These conditions create hazardous area lighting problems, increasing industrial safety risks. Inadequate task lighting often leads to poor visibility, hindering precise work and increasing the likelihood of human error. This directly contributes to explosion risk zones.

Harsh conditions in these environments, including extreme temperatures, corrosive atmospheres, and vibrations, place a substantial maintenance burden on industrial lighting systems. Frequent failures and replacements disrupt operations and incur high costs. Addressing these issues requires robust, reliable, and compliant lighting solutions that can withstand severe conditions while providing effective illumination and warning capabilities. The failure to address these challenges can result in severe consequences, including injuries, fatalities, and significant financial losses due to accidents or regulatory non-compliance.

Advanced Local and Caution Spotlight Solutions

We develop advanced local and caution spotlight solutions to counteract the inherent dangers of hazardous industrial settings. Our specialized fittings integrate cutting-edge explosion proof spotlight technology and robust construction, providing both illumination and critical warning signals. These solutions are designed to meet stringent safety standards, including ATEX certified luminaires and IECEx certifications, ensuring reliable operation in the most demanding environments. The benefits of LED caution lighting include energy efficiency, extended operational life, and superior light output compared to traditional systems. We prioritize industrial spotlight durability and integrated safety signaling to enhance overall site safety.

Our products, such as the BBJ86 Explosion-proof Audio and Visual Caution Spotlight Fitting, exemplify these advancements. This fitting features a high-quality steel lamp body with a powder-coated surface, ensuring reliable performance in severe conditions exposed to moisture, vibration, or corrosion. It includes a constant current and constant voltage LED driver with overload protection and EOL functions. The wide voltage input ensures compatibility across various projects and regions. The transparent cover material is glass, resistant to 4J impact, providing enhanced durability. It also offers a number of flashes at 150-160 times/min and a sound intensity of 110-120dB (R=1m), providing clear audio-visual warnings. The ambient temperature range is -60℃ to +60℃, with an IP66 degree of protection.

Precision Illumination and Warning Capabilities

Our local caution spotlight fittings offer precision illumination and critical warning capabilities. These devices provide focused task lighting, ensuring optimal visibility for complex operations in hazardous zones. Beyond mere illumination, they incorporate visual warning systems, such as flashing lights, to alert personnel to immediate dangers or operational changes. This dual functionality of light and warning enhances safety by providing clear, directional safety lights. High visibility spotlights are crucial for preventing accidents and ensuring prompt responses in dynamic industrial environments. These integrated features significantly reduce the risk of incidents by making hazards immediately apparent.

Robust Design and Compliance Standards

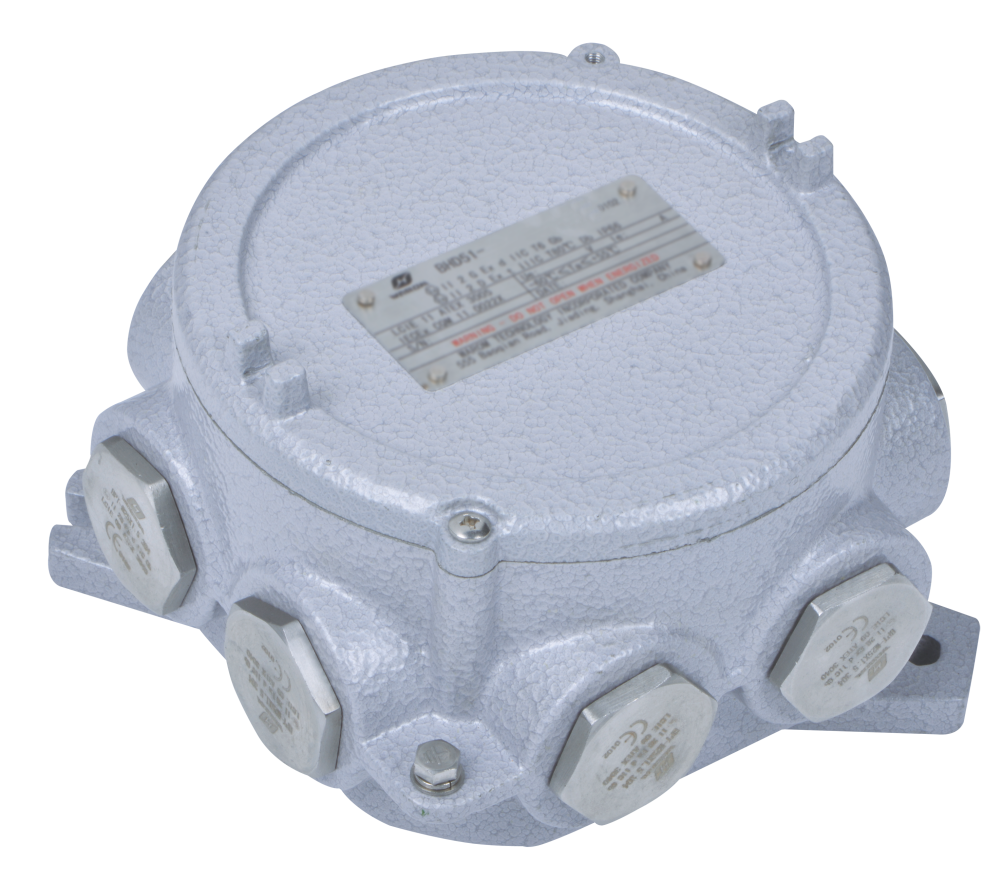

Our specialized fittings are engineered with robust design and adherence to stringent compliance standards. This ensures their reliability and safety in extreme conditions. The explosion proof construction utilizes high-strength materials, such as copper-free aluminum alloy and GRP (glass fiber-reinforced polyester resin), providing superior protection against impacts and environmental stressors. These materials also contribute to corrosion resistant lighting, extending product lifespan in harsh chemical or marine environments. Our products achieve an IP rated spotlight classification (e.g., IP66), signifying comprehensive protection against dust and powerful water jets. We strictly comply with hazardous location standards like ATEX and IECEx, ensuring our equipment meets global safety requirements for explosive atmospheres.

| Feature | BBJ86 Explosion-proof Audio and Visual Caution Spotlight Fitting |

|---|---|

| Material | High-quality steel lamp body, powder-coated surface |

| Cover Material | Glass, resistant to 4J impact |

| Flashes | 150-160 Times/min |

| Sound Intensity | 110-120dB (R=1m) |

| Ambient Temp. | -60℃ to +60℃ |

| Protection | IP66 |

Operational Value and Long Term Benefits

Implementing our advanced spotlight solutions delivers significant operational value and long-term benefits. These solutions lead to reduced operational costs through energy efficiency and minimized maintenance requirements. The enhanced worker safety, achieved through superior illumination and integrated warning systems, directly translates into fewer accidents and associated liabilities. This also improves industrial efficiency by ensuring continuous, safe operations. Our sustainable lighting solutions contribute to environmental responsibility while providing reliable performance. Deploying compliant equipment helps achieve compliance risk reduction, avoiding costly penalties and operational shutdowns. Investing in these technologies safeguards personnel and optimizes overall business performance.

We encourage you to explore our wide range of explosion-proof lighting and electrical systems to find solutions tailored to your specific needs.

Real World Application: Tilenga Project Success

Our expertise in hazardous area lighting was recently demonstrated in the Tilenga Project in Uganda. This large-scale oil and gas development, including wellpads, a Central Processing Facility (CPF), and pipelines within Murchison Falls National Park, presented extreme environmental and safety challenges. We supplied explosion-proof lighting and electrical systems for the project, ensuring robust safety measures. Our solutions contributed to zero safety incidents throughout the project’s implementation. The installed systems provided energy efficiency, low maintenance, and reliable performance under severe conditions. The project successfully met all safety, environmental, and performance requirements on schedule, showcasing our capability to deliver effective solutions in complex, hazardous environments. This success reinforces our authority and experience in providing critical safety infrastructure for global industrial projects.

For further insights into our broader safety solutions, we invite you to review our 《Service & Support》.

Connect with Our Experts

Do you need specialized lighting solutions for your hazardous industrial environment? Contact us today for tailored advice and robust explosion-proof products. Our team is ready to assist you.

Email: gmb@warom.com

Tel: +86 21 39977076 +86 21 39972657

FAQs

What makes a spotlight ‘caution’ rated for hazardous zones?

Caution-rated spotlights are designed with specific features, such as explosion-proof enclosures, integrated warning signals (e.g., flashing lights), and robust materials. These features allow them to operate safely and provide critical visual alerts in environments with flammable gases, vapors, or dust. They meet stringent safety standards like ATEX or IECEx, ensuring they do not become ignition sources.

How do local spotlight fittings enhance worker safety?

Local spotlight fittings enhance worker safety by providing focused, high-intensity illumination precisely where it is needed for critical tasks. This reduces shadows and improves visibility. When combined with caution features, they also serve as immediate visual warnings for potential hazards or operational changes, preventing accidents in hazardous zones and improving situational awareness.

Are WAROM’s local caution spotlights compliant with international safety standards?

Yes, WAROM’s local caution spotlight fittings are engineered to meet and often exceed international safety standards, including ATEX and IECEx certifications. This ensures their safe and reliable operation in diverse hazardous industrial environments globally. Our commitment to these standards is demonstrated in projects like Tilenga, where our products performed flawlessly under extreme conditions.

With over a decade of experience, he is a seasoned Explosion-Proof Electrical Engineer specializing in the design and manufacture of safety and explosion-proof products. He possesses in-depth expertise across key areas including explosion-proof systems, nuclear power lighting, marine safety, fire protection, and intelligent control systems. At Warom Technology Incorporated Company, he holds dual leadership roles as Deputy Chief Engineer for International Business and Head of the International R&D Department, where he oversees R&D initiatives and ensures the precise delivery of design documentation for international projects. Committed to advancing global industrial safety, he focuses on translating complex technologies into practical solutions, helping clients implement safer, smarter, and more reliable control systems worldwide.

Qi Lingyi