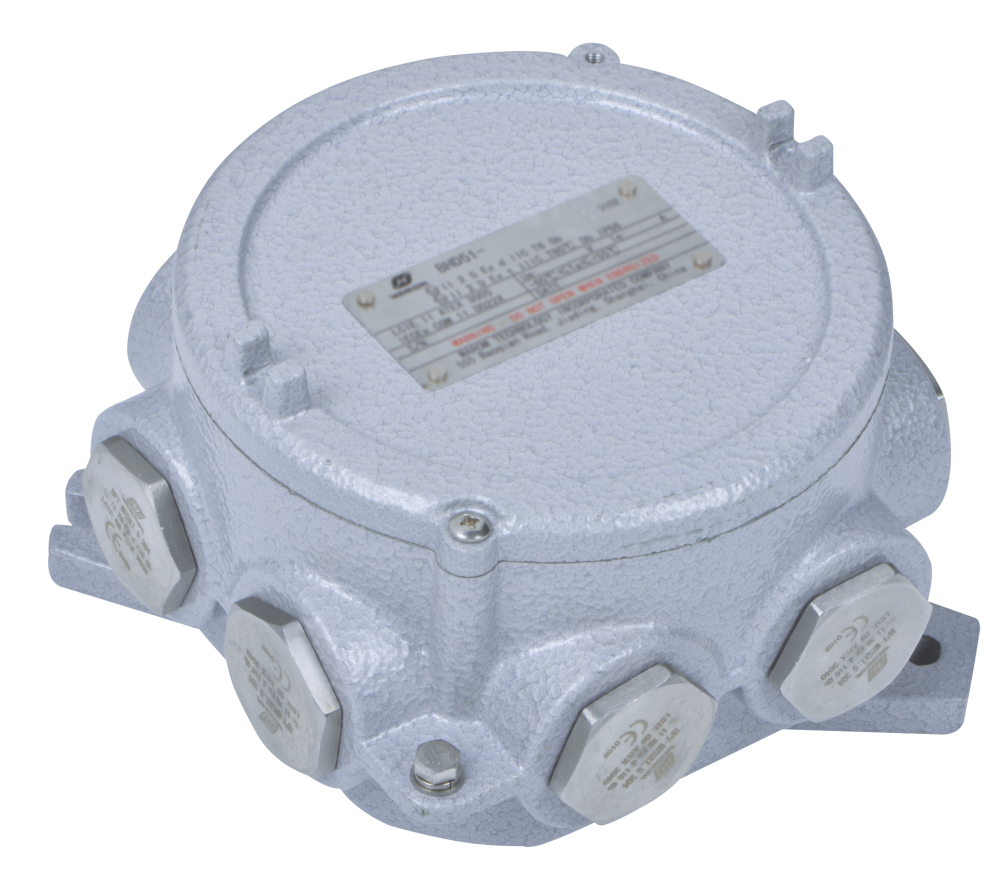

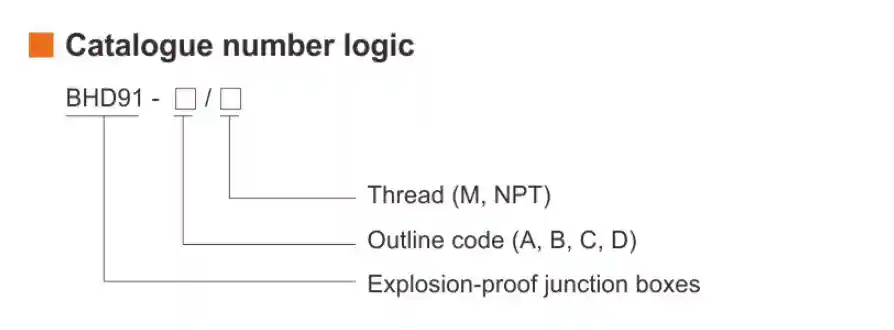

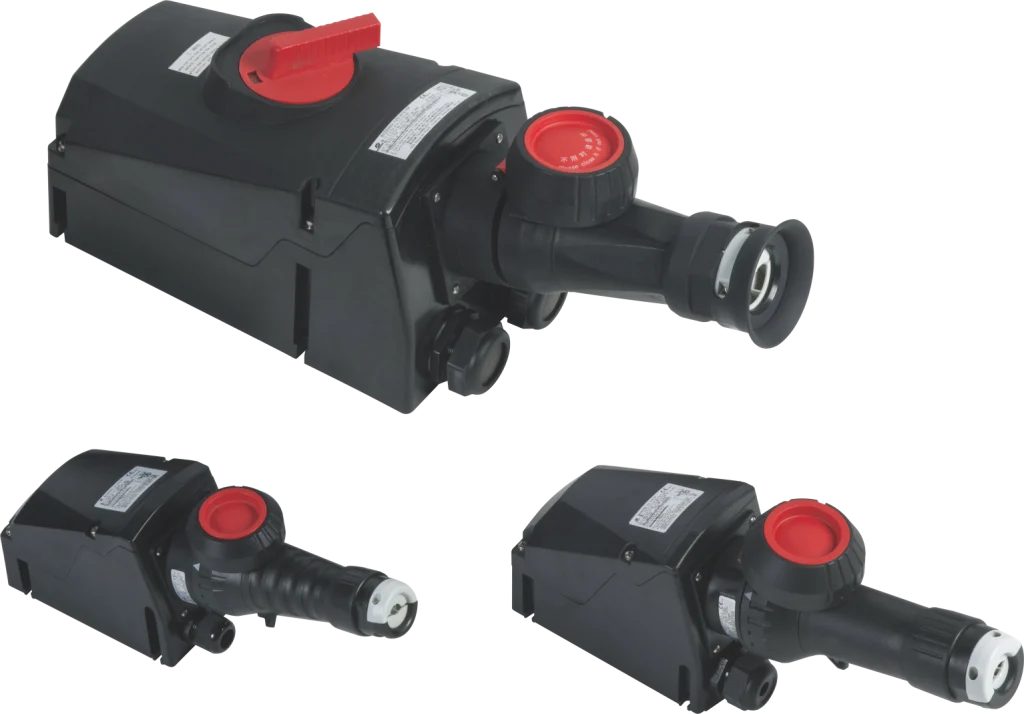

BHD91 Series Explosion-proof Junction...

- ◆ Constructed with a high-strength copper-free aluminum alloy, this explosion-proof junction boxes features robustness, corrosion resistance and a high protection level (IP66).

- ◆ The flameproof junction box treated with anti-static coating and all fasteners are anti-loosening.

- ◆ Use flameproof junction enclosure and sealed structure to contain and isolate any potential electric sparks or high-temperature faults that may occur at cable connections within the enclosure.

- ◆The IP66 rating prevents internal component of the ex junction boxes aging and corrosion, which extends system life and lowers maintenance costs.

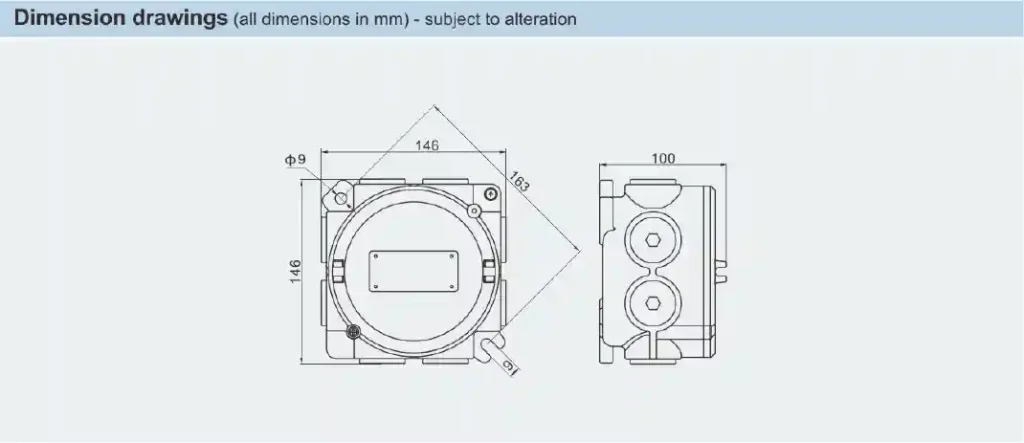

TECHNICAL DATA

Explosion Protection Type

- Standards: CENELEC, IEC, NEC.

- Zones: Zone 1 and Zone 2; Zone 21 and Zone 22; Class I, Zone 1 and Zone 2; Class I, Division 1, Groups A, B, C, D.

- Explosion Protection Ratings:

- IECEx (Gas and dust): Ex db IIC T6 Gb; Ex tb IIIC T80°C Db IP66.

- ATEX (Gas and dust): II 2 G Ex db IIC T6 Gb; II 2 D Ex tb IIIC T80°C Db.

Product Parameters

- Product Type: BHD91.

- Material:

- Enclosure: Copper-free Aluminium Alloy, powder coated surface.

- Exposed fastener: Stainless steel.

- Enclosure Color: Window grey (RAL7040).

- Rated voltage: Max. 500V AC.

- Rated current and Terminal data:

- Cross section 2.5mm² (Rated current: 24A, Terminal number: 12).

- Cross section 4mm² (Rated current: 32A, Terminal number: 10).

- Cross section 6mm² (Rated current: 41A, Terminal number: 8).

- Degree of protection: IP66.

- Ambient temperature: -60°C ~ +60°C.

- Internal & external earthing: M5/M5.

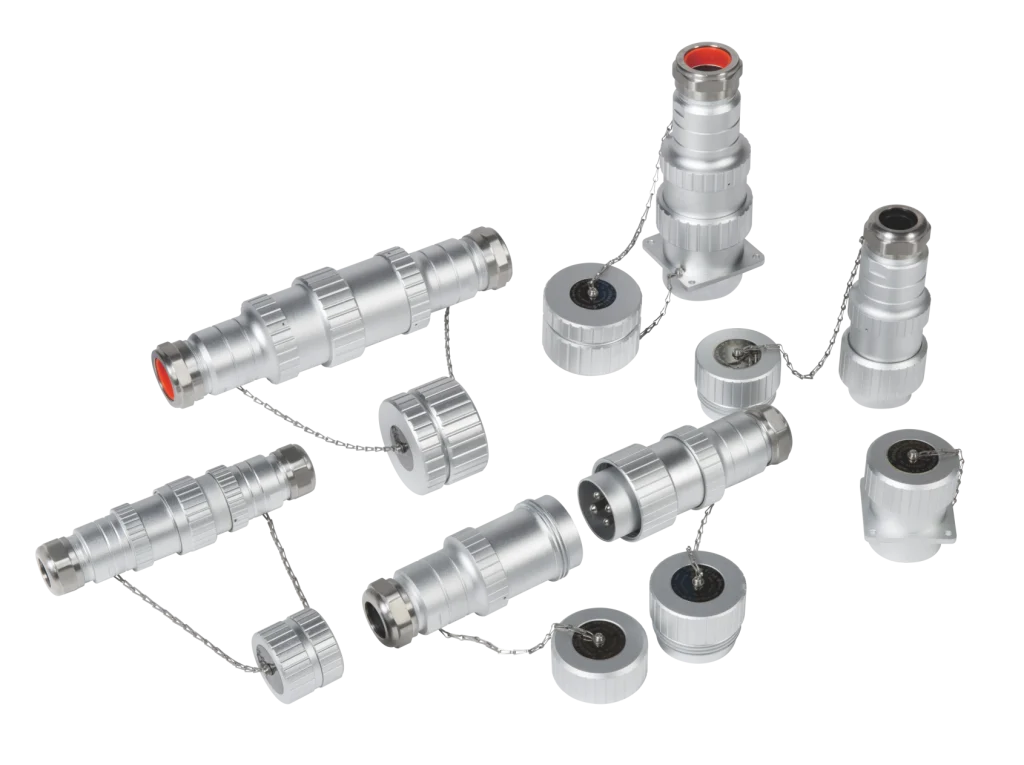

- Cable entries: Standard M☐ x 1.5 plugs; NPT☐ plugs on request.

- Cable glands: Optional, DQM-II (Ex d) or DQM-III (Ex d) is recommended.

Product Classification & Origin

- HS code: 853650.

- Country of origin: China.

Applicable Industries

- Explosion-Proof Junction Boxes are engineered for hazardous environments including petrochemical, natural gas, coal, metallurgy, military, nuclear power, aerospace, and more.

- Performance: Delivers long-lasting, corrosion-resistant performance in harsh conditions including high temperatures, heavy dust, and corrosive gases.

- Safety Role: It is a critical link within modern industrial safety frameworks, functioning as an engineered safety system rather than just a basic enclosure.

Credibility

- Certifications: Warom Explosion-Proof Terminal Boxes meet stringent global requirements including ATEX, IECEx, and EAC certifications.

- Reliability: Features a T5-T6 temperature rating and IP66 protection.

- Service: Warom supports projects with a seamless, end-to-end service from initial design assessment to final certification.

FAQ

- Q1: What are the principles of explosion-proof junction boxes?

- A: Based on two main types: Flameproof (Ex d), which uses precision gaps to cool flames, and Increased Safety (Ex e), which prevents arcs/sparks via enhanced insulation.

- Q2: Are the terminal boxes need regular maintenance?

- A: Yes. Critical checks include inspecting flameproof surfaces, ensuring tight fasteners, and replacing damaged parts with original factory spare parts.

- Q3: Can internal wiring be connected carelessly after installing the ex-terminal boxes?

- A: Absolutely not! The box only provides “containment.” Internal electrical connections must comply with electrical standards.

- Q4: Is it fully waterproof/dustproof?

- A: Depends on its IP rating. Typical hazardous location junction boxes (such as IP66/67) resist powerful water jets or temporary immersion.