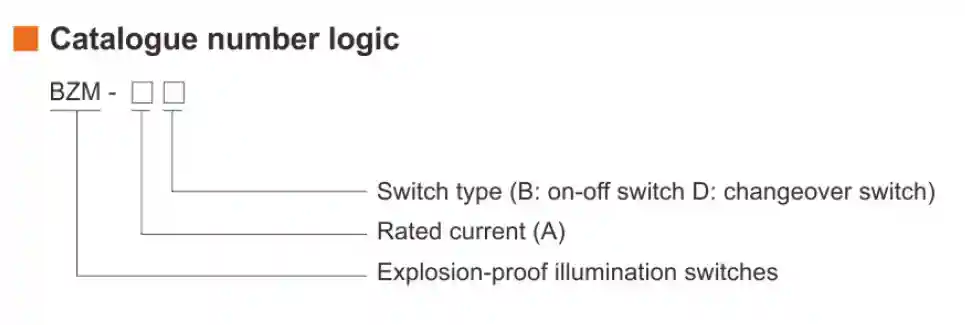

BZM Series Explosion-proof Illumination...

- ◆ This explosion proof Illumination Switches features a high-strength copper-free aluminum alloy housing with a specialized flameproof surface.

- ◆ Explosion proof limit switch withstands internal explosion pressure while cooling flames and reducing gas temperature through narrow gaps, preventing ignition of external hazardous atmospheres.

- ◆ The explosion proof enclosure includes anti-static coating and all fasteners are anti-loosening.

- ◆ Switches are available in both power ON/OFF and two-way control configurations.

TECHNICAL DATA

Explosion Protection Type

- Standards: CENELEC, IEC, NEC.

- Zones: Zone 1 and Zone 2; Zone 21 and Zone 22; Class I, Zone 1 and Zone 2; Class I, Division 1, Groups A, B, C, D.

- Explosion Protection Ratings:

- IECEx (Gas and dust): Ex db IIC T6 Gb; Ex tb IIIC T80°C Db.

- ATEX (Gas and dust): II 2 G Ex db IIC T6 Gb; II 2 D Ex tb IIIC T80°C Db.

Product Parameters

- Product Type: BZM.

- Material:

- Enclosure: Copper-free Aluminium Alloy, powder coated surface.

- Exposed fastener: Stainless steel.

- Enclosure Color: Window grey (RAL7040).

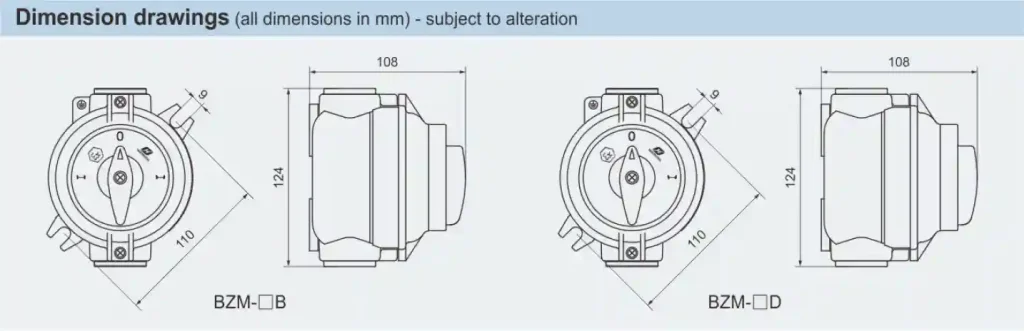

- Switch functions: On-off switch or changeover switch.

- Rated voltage: Max. 250V AC.

- Rated current: 16A, 25A.

- Degree of protection: IP66.

- Ambient temperature: -40°C ~ +60°C.

- Internal/external earthing: M5/M5.

- Cable entries: Standard 2 x M25 x 1.5 plugs; 2 x NPT3/4″ plugs on request.

- Cable glands: Optional, DQM-II (Ex d) or DQM-III (Ex d) is recommended.

Product Classification & Origin

- HS code: 853650.

- Country of origin: China.

Applicable Industries

- Explosion-Proof Illumination Switches are specifically engineered for hazardous environments, including petrochemical, natural gas, coal, metallurgy, military, nuclear power, and aerospace.

- Applications: Firefighting, pharmaceuticals, textiles, grain & oil, municipal services, public security, shipping, ports, railways, and more.

- Safety Features: Designed with a robust explosion-proof structure to ensure safety by locking away potential ignition within a robust enclosure, eliminating risks at an initial reaction level.

Credibility

- Certifications: Warom Explosion-Proof Switches are fully certified to ATEX, IECEx, and EAC standards for global compliance.

- Performance: Features a wide operating temperature range (-40°C to +60°C), corrosion resistance against chemicals, and an IP66 rating.

- Reliability: Authentically certified “Flameproof Switches” (Ex d) backed by stringent scientific measurements.

FAQ

- Q1: What is an explosion-proof switch? How does it differ from a standard switch?

- A: It is specifically designed for environments with flammable substances; while standard switches expose electrical arcs, these use a flameproof enclosure to contain internal sparks or explosions.

- Q2: What does the marking “Ex db IIC T6” on the surface mean?

- A: “Ex” is explosion-protected; “db” is flameproof enclosure; “IIC” is suitable for gas groups including hydrogen and acetylene; “T6” indicates a maximum surface temperature of ≤85°C.

- Q3: What does the IP66 rating signify?

- A: “6” for dust-tight and the second “6” for protection against powerful water jets, ensuring reliability in indoor and outdoor environments.

- Q4: Can these switches be used in chemical plants and flour mills?

- A: Yes, as they offer gas protection (Ex db) for chemical plants and dust protection (Ex tb) for flour mills.

- Q5: What are critical installation precautions?

- A: Proper installation is essential; fully tighten bolts, use sealant/oxide seals, and ensure reliable grounding to prevent static buildup.

- Q6: What does regular maintenance involve?

- A: Inspecting the housing for damage, cleaning flameproof joint surfaces, and checking fastener tightness; all performed by qualified personnel.