Lighting in hazardous industrial settings carries real weight. The right fixtures prevent incidents, protect people, and keep operations steady. From how explosion proof floodlights are built to the certifications that govern them, and from field-proven deployments to the gains in reliability and cost, what follows lays out why these systems matter when conditions get tough.

Understanding Explosion Proof Floodlights

This section defines explosion-proof floodlights, clarifies their purpose, and shows how they differ from standard lighting. It explains the science of explosion protection and the principles that prevent ignition in hazardous atmospheres. The aim is to build a clear understanding of the safety role these specialized lighting solutions play.

1. What Makes a Floodlight ‘Explosion Proof’

Explosion-proof floodlights are engineered to contain any internal explosion so that flammable gases, vapors, dusts, or fibers around the fixture are not ignited. Several protection methods work toward that outcome. Flameproof enclosures are built to withstand an internal explosion and cool escaping hot gases below the ignition temperature of the external atmosphere. Intrinsic safety limits electrical and thermal energy to prevent ignition. Increased safety designs reduce the chance of sparks or hot surfaces. Dust ignition protection blocks dust ingress and prevents accumulation on hot surfaces. Together, these designs support safe operation in hazardous locations.

2. Key Certifications and Standards

Global and regional certifications confirm that explosion-proof equipment meets strict safety requirements. ATEX (Atmosphères Explosibles) is a mandatory European directive, while IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) is an international certification system. Other local standards, such as UL or CSA, apply in specific regions. These certifications classify equipment by the hazardous zones where they can be safely used, including Zone 1 (gases/vapors present occasionally), Zone 2 (gases/vapors present rarely), Zone 21 (combustible dusts present occasionally), and Zone 22 (combustible dusts present rarely). Compliance with these standards helps prevent accidents.

| Standard | Scope | Key Focus | Zones Covered |

|---|---|---|---|

| ATEX | European Union | Legal compliance for equipment and protective systems | Zones 0, 1, 2 (Gas); 20, 21, 22 (Dust) |

| IECEx | International | Global acceptance for equipment in explosive atmospheres | Zones 0, 1, 2 (Gas); 20, 21, 22 (Dust) |

| UL (e.g., UL 1203) | North America | Safety testing and certification for electrical equipment | Class I, II, III, Divisions 1 & 2 |

| CCS | Marine | Specific requirements for marine electrical equipment | Various marine hazardous areas |

Addressing Industrial Safety Challenges

Hazardous locations present real safety pressures. Poor lighting increases the risk of explosions, fires, and worker injuries, which drives financial losses, downtime, and reputational damage. Robust explosion-proof solutions are a practical way to cut those risks. Investing in certified equipment supports continuous, safe operation while safeguarding assets and personnel.

WAROM’s Solutions for Hazardous Environments

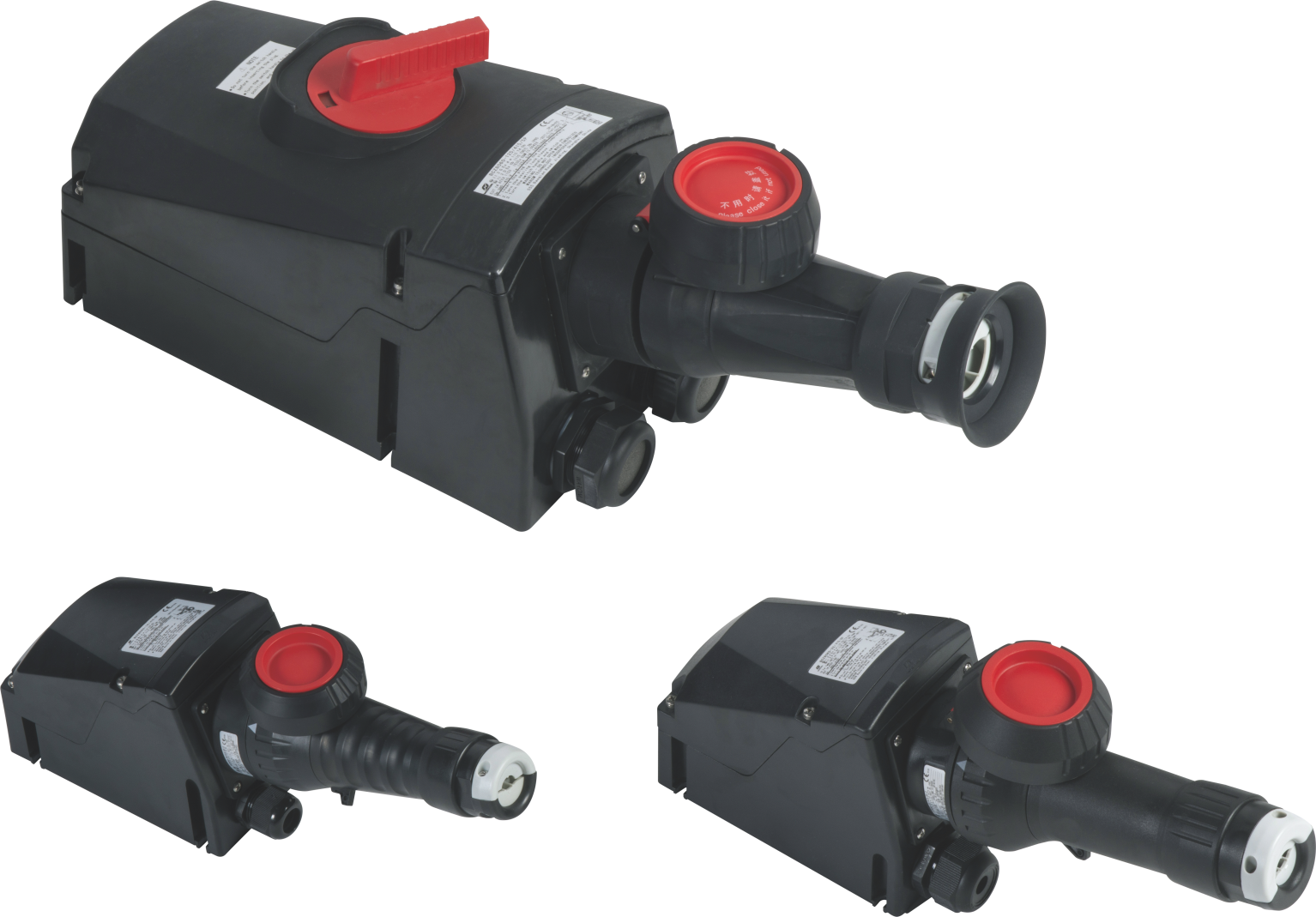

WAROM provides a full range of explosion-proof lighting solutions for hazardous environments. The products integrate advanced LED technology for strong illumination and energy efficiency. Construction is built for durability in severe conditions with moisture, vibration, or corrosion. All products comply with IEC 60079 and EN 60079. This focus addresses safety, operational, and maintenance priorities for industrial clients. The range includes specialized explosion proof light fittings explosion proof marine products and explosion proof camera systems, ensuring complete safety coverage.

Unlocking Value and Performance

Investing in WAROM’s explosion-proof floodlights brings measurable value and performance. The solutions improve operational safety, lower energy consumption, and cut maintenance costs. Compliance with international safety standards supports confidence in critical industrial settings. Products are built for a long service life and steady performance in demanding conditions.

1. Enhanced Safety and Compliance

WAROM’s explosion-proof floodlights are engineered to support safer working environments. They limit the risk of explosions by containing potential ignition sources and are certified for hazardous zones. The products meet rigorous standards like IEC 60079 and EN 60079, maintaining regulatory compliance. Robust design and certification help prevent catastrophic incidents and protect personnel. For more information on our commitment to safety, refer to our 《Certificate》 page.

2. Long-Term Cost Savings and Efficiency

LED explosion-proof floodlights deliver strong economic advantages. They use significantly less electricity than traditional lighting technologies (like HID or fluorescent) while providing superior illumination. Durable construction and long lifespan reduce replacements and maintenance. This cuts downtime and associated labor costs, leading to notable long-term savings and better operational efficiency.

Real-World Applications and Success Stories

WAROM’s explosion-proof floodlights perform across diverse industrial applications. Case studies show practical effectiveness and reliability. Consistent product quality and knowledgeable support reinforce trust in hazardous environments.

1. Tilenga Project in Uganda

For the Tilenga project in Uganda, WAROM supplied explosion-proof lighting and electrical systems for wellpads, a CPF, and pipelines within Murchison Falls National Park. The solutions delivered zero safety incidents, high energy efficiency, and low maintenance. Products proved reliable under extreme environmental conditions and met all safety, environmental, and performance requirements on schedule.

2. General Paint Electrical Safety Upgrade

In Mexico, WAROM addressed serious electrical safety hazards at General Paint, a chemical plant with flammable gas and dust risks. The team provided a customized explosion-proof solution, including gas detectors, explosion-proof plugs and sockets, junction boxes, distribution boxes, static electricity discharge devices, and anti-corrosion equipment. This three-month project improved safety, prevented potential fires or explosions, and integrated WAROM’s products into the customer’s procurement system. The outcome built trust and established a replicable technical-marketing model.

3. Fushilai Pharmaceutical CM/CDMO Construction

WAROM secured the bid for explosion-proof equipment for Suzhou Fushilai Pharmaceutical’s new 48,000 m² facility. The supply included distribution boxes for workshops, warehouses, tank farms, and pump controls. Through early coordination with the promoter, design institute, and project owner, delivery was timely and quality-focused. The project strengthened customer trust, expanded presence in the pharmaceutical sector, and established a replicable model for multi-party coordination in complex industrial projects.

Call to Action

Ready to enhance safety and efficiency in your hazardous industrial environment? Contact WAROM TECHNOLOGY INCORPORATED COMPANY today for a customized explosion-proof floodlight solution. Our experts are available to discuss your specific project requirements and provide a comprehensive consultation. Call us at +86 21 39977076 or +86 21 39972657, or email gmb@warom.com to ensure uncompromised safety and performance.

FAQs

1. What is the difference between ATEX and IECEx certifications?

ATEX is a mandatory European directive for equipment used in potentially explosive atmospheres, while IECEx is an international certification system that facilitates global trade of equipment for hazardous locations. Both ensure high safety standards, but ATEX is legally binding within the EU, whereas IECEx is a voluntary scheme recognized worldwide.

2. How do LED explosion-proof floodlights contribute to energy savings?

LED explosion-proof floodlights consume significantly less power than traditional lighting technologies (like HID or fluorescent) while providing superior illumination. Their longer lifespan also reduces maintenance and replacement costs, leading to substantial long-term energy and operational savings for industrial facilities.

3. In which industrial zones are explosion-proof floodlights typically required?

Explosion-proof floodlights are used in hazardous industrial zones classified as Zone 1 (gases/vapors present occasionally), Zone 2 (gases/vapors present rarely), Zone 21 (combustible dusts present occasionally), and Zone 22 (combustible dusts present rarely). The specific zone classification dictates the type of explosion protection required.

4. What factors should I consider when selecting an explosion-proof floodlight?

Key factors include the hazardous zone classification of your facility, required lumen output and beam angle, material durability (e.g., corrosion resistance), ingress protection (IP) rating, operating temperature range, energy efficiency (LED preferred), and specific certifications (ATEX, IECEx, UL, etc.) relevant to your region and industry.

5. Can WAROM provide customized explosion-proof lighting solutions for unique project requirements?

Yes, WAROM specializes in providing customized explosion-proof lighting and electrical solutions. As demonstrated in our case studies, we work closely with clients, design institutes, and project owners to develop tailored solutions that meet specific operational, safety, and environmental requirements, ensuring optimal performance and compliance.

With over a decade of experience, he is a seasoned Explosion-Proof Electrical Engineer specializing in the design and manufacture of safety and explosion-proof products. He possesses in-depth expertise across key areas including explosion-proof systems, nuclear power lighting, marine safety, fire protection, and intelligent control systems. At Warom Technology Incorporated Company, he holds dual leadership roles as Deputy Chief Engineer for International Business and Head of the International R&D Department, where he oversees R&D initiatives and ensures the precise delivery of design documentation for international projects. Committed to advancing global industrial safety, he focuses on translating complex technologies into practical solutions, helping clients implement safer, smarter, and more reliable control systems worldwide.

Qi Lingyi