North Field South LNG Project

- Project Overview

As a benchmark enterprise in China’s explosion-proof lighting and electrical sector, WAROM TECHNOLOGY INCORPORATED COMPANY (hereinafter referred to as “WAROM Technology”) has successfully won the core supply contract for Qatar’s North Field South (NFS) LNG Project. The contract covers multiple electrical product packages, including: an integrated lighting package consisting of explosion-proof/three-proof lighting fixtures, explosion-proof/three-proof plugs, explosion-proof/three-proof switch boxes, 2m-10m fixed light poles and 30m lifting light poles; a power distribution equipment package with 300 explosion-proof distribution boxes; and a low-voltage power distribution package expected to include 200 low-voltage distribution boards (LV DB). The total project value exceeds 10 million US dollars, with a three-year phased supply implementation cycle. This cooperation is not only a milestone for WAROM Technology in deepening its presence in the Middle East energy market but also highlights the core performance capabilities of Chinese intelligent manufacturing in international high-end energy projects.

- Customer background and challenges

Qatar’s North Field is the world’s largest proven natural gas field, and its North Field South LNG Project is the core project of the country’s energy strategy upgrading, with the core goal of increasing LNG production capacity to meet global energy demand. The project owner is a leading enterprise in Qatar’s energy sector, setting strict standards for equipment safety redundancy, weather resistance thresholds, and operational stability: Firstly, the LNG plant area is an explosive and flammable hazardous environment, requiring electrical products to meet the IECEx Zone 2 international standard for explosion-proof grades; Secondly, Qatar’s climatic conditions of high temperature (up to 55℃ in extreme cases), high humidity (RH 100%), and strong sandstorms place extreme demands on equipment’s corrosion resistance (ISO 12944 C4-H), aging resistance, and sealing performance; Thirdly, the long project cycle and diverse product categories require the establishment of a full-cycle supply chain management and control system to ensure that the supply progress accurately matches the project milestones.

- Our Solution

In response to the project’s high safety level and complex operating conditions, WAROM Technology established an inter-departmental special working group (including R&D, production, quality control, and logistics teams) to customize electrical solutions that comply with IEC and local Qatari standards. The core product system covers three categories, achieving full-scenario adaptation in the LNG plant area:

Explosion-Proof Lighting System :

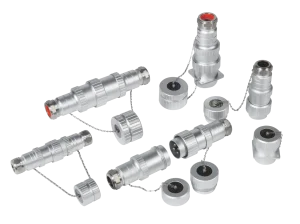

Core configurations include Zone 2-class BnY81 explosion-proof linear lights, HRND95 floodlights, and HRNT95 floodlights (used in main operation areas, with high luminous efficiency ≥150lm/W and service life ≥50,000h), supplemented by various three-proof lights (used in auxiliary areas, with protection grade IP66). It is matched with 2m-10m hot-dip galvanized anti-corrosion fixed light poles (zinc layer thickness ≥85μm) and 30m electric lifting light poles (wind resistance grade 44m/s, with power-off self-locking function and anti-fall protection), ensuring no dead ends in lighting coverage in hazardous environments. In addition, electrical accessories include: BZC8050 series explosion-proof control boxes, BXJ8050 series explosion-proof junction boxes, BCZ8060 series explosion-proof plugs, etc.

Explosion-Proof Power Distribution Equipment :

More than 300 BXMD8061 series explosion-proof distribution boxes, with explosion-proof type Ex d e IIC T4/T5, SS316 shell. The self-owned spray system combined with AkzoNobel powder ensures compliance with C4-H requirements. The overall design adopts a composite structure of explosion-proof cavity + increased safety cavity, with internally configured self-developed explosion-proof series components, integrating overload protection (trip current accuracy ±5%), short-circuit protection (breaking capacity 36kA), and leakage protection (with external testing function, and some operating currents reaching 300mA) functions. It is compatible with the 415V/50Hz voltage system of the LNG plant area, ensuring safe and stable power distribution.

Low-Voltage Power Distribution System :

More than 200 FXMD series low-voltage distribution boards (LV DB) are manufactured in strict accordance with IEC standards, adopting GGD-type cabinet structure (protection grade IP41). Internally equipped with ABB XT and Schneider CVS series circuit breakers, it has modular splicing function (expandable number of circuits ≥200), and built-in forced ventilation and heat dissipation system (heat dissipation efficiency ≥80W/℃), ensuring full-load operation in high-temperature environments of 55℃. In addition, prominent application technologies include dual incoming lines switched by MCO combination, mechanical interlocking of main incoming lines, equipped with leakage monitoring module (leakage adjustable 30mA-30A and 0.02-5s adjustable), and automatic temperature control unit, etc.

All products have passed extreme environment tests by authoritative third-party institutions (CQM/CNEX): In temperature cycles from -40℃ to 60℃, level 14 sandstorms (wind speed ≥44m/s), and salt spray corrosion (720/1440h) tests, the deviation of various performance parameters is ≤3%, and the explosion-proof performance and weather resistance are better than the requirements of the project technical specification.

- Implementation Process &Timeline

Based on the PMBOK project management system, WAROM Technology established a full-process management and control mechanism of “R&D – Production – Quality Control – Delivery”, with key timeline plans as follows:

Q1-Q2 2024: Complete technical clarification and contract signing, establish a special working group, output product technical drawings and pass the owner’s review; Q3-Q4: Complete sample trial production and explosion-proof certification (ATEX 2014/34/EU);

January-October 2025: Launch mass production of the first batch of products, implement three-level quality control of “raw material IQC – process IPQC – finished product FQC”, and conduct 100% inspection of key processes (explosion-proof cavity welding, seal assembly);

November 2025: The first batch of products passed the joint inspection by the owner and SGS, with 100% one-time qualification in explosion-proof performance, weather resistance, and electrical parameter tests, and an acceptance pass rate of 100%;

Q1-Q4 2026: Deliver in 3 batches according to the project progress, complete the supply of 150 explosion-proof distribution boxes and 80 LV DBs, and provide on-site installation technical disclosure simultaneously;

Q1-Q3 2027: Complete the delivery of the remaining 150 explosion-proof distribution boxes, 120 LV DBs, and supporting lighting fixtures, and provide 12-month after-sales operation and maintenance support.

- Results & Data Highlights

Cooperation Scale: The total project value exceeds 10 million US dollars, covering 7 categories and 23 specifications of lighting and electrical products, making it one of WAROM Technology’s largest single energy-related orders in the Middle East region;

Quality Performance: The qualification rate of key indicators (explosion-proof grade, protection grade, temperature rise limit) of the first batch of products is 100%, passing the dual certification of third-party INTERTEC, engineering company TEN, and the owner, with no quality deviation records;

Delivery Performance: As of December 2025, the first batch of goods has been delivered 100% according to the contract schedule, with a delivery punctuality rate of 100% and a logistics damage rate of 0;

Market Value: Strengthen the core supply chain relationship with Qatar’s energy sector, enhance the status of qualified supplier in the owner Qatar Energy, and lay the foundation for further expanding into the oil and chemical fields in the Middle East.

- Customer Feedback

“The NFS project is a key project of Qatar’s energy strategy, and the safety and reliability of equipment directly determine the project’s commissioning cycle. Among global supplier bids, WAROM Technology stood out with the technical accuracy of its customized solutions and full-process management and control capabilities. The first batch of delivered products has passed third-party tests, and their explosion-proof performance and weather resistance are better than the technical specification requirements. Especially in the 55℃ high-temperature load test, the equipment showed outstanding stability in operating parameters. WAROM Technology’s professional performance capabilities have provided a solid guarantee for the smooth progress of the project. We have further upgraded its status as a core supplier and will continue to deepen cooperation.”——Qatar NFS Project Team

- Lessons & Insights

This cooperation with Qatar’s NFS project is a typical case of WAROM Technology practicing the strategy of “Technology-Driven, Global Service”, providing replicable experience for Chinese explosion-proof electrical enterprises to explore the international high-end energy market:

Technical Compliance is the Prerequisite for Access: It is necessary to deeply interpret the technical standards of the target market (such as Qatar’s KEC standard), integrate international certifications (ATEX/IECEx) with localized needs, and form differentiated technical solutions;

Full-Chain Management and Control is the Core of Performance: For long-cycle projects, it is necessary to establish a closed-loop management of “Demand – R&D – Production – Delivery – Operation and Maintenance”, and realize real-time traceability of progress and quality through digital systems;

Localized Service is the Extension of Cooperation: Layout regional logistics hubs and technical support centers in advance, provide on-site installation guidance and rapid response operation and maintenance, and enhance customer cooperation stickiness.

In the future, WAROM Technology will continue to focus on technological innovation in the explosion-proof electrical field, deepen the global supply chain layout, and provide safe, efficient, and customized solutions for more major international energy projects.