In hazardous environments, lighting choices carry real consequences. We aim for fixtures that work hard, comply with strict standards, and hold up under tough conditions. Time after time, the right illumination prevents incidents, supports productivity, and keeps operations within regulations. Below, we cover the essentials of industrial pendant light fittings, their role in hazardous areas, and the advanced solutions we provide.

Understanding Pendant Light Fittings for Industrial Use

Industrial pendant light fittings are specialized luminaires suspended from a ceiling and used across large industrial spaces. Depending on the task, they deliver focused or broad illumination. Built with rugged materials to handle harsh conditions, they stand apart from typical commercial or residential lighting.

1. Defining Industrial Pendant Lighting

Industrial pendant lighting serves large areas such as warehouses, factories, and workshops. These fixtures are built for durability and performance in demanding environments. They feature heavy-duty construction and offer various light distribution patterns.

2. Key Features of Robust Pendant Light Fittings

Robust pendant light fittings bring several key attributes. Material durability, such as high-quality steel or copper-free aluminum alloy, supports long service life. Ingress Protection (IP) ratings like IP66 indicate resistance to dust and powerful water jets. Basic electrical considerations include wide voltage input and protection against overcurrent.

| Feature | Description | Benefit |

|---|---|---|

| Material | Steel, Copper-free Aluminum Alloy | Enhanced durability and corrosion resistance |

| IP Rating | IP66 | Protection against dust and strong water jets |

| Driver | Constant current/voltage, overload protection | Stable operation and extended lifespan |

| Temperature | Wide ambient temperature range (e.g., -60°C to +60°C) | Reliable performance in extreme climates |

Ensuring Safety with Explosion-Proof Pendant Lighting

This section covers the specific requirements for pendant light fittings in hazardous locations, including risks, regulations, and the technologies used to mitigate them, with emphasis on the explosion-proof aspect.

1. Hazardous Area Classification and Lighting Needs

Hazardous zones classify areas by the likelihood of flammable substances being present. Zone 1 and Zone 2 indicate areas where explosive gas atmospheres are likely or unlikely to occur, respectively. Certifications like ATEX (Europe) and IECEx (international) verify that equipment meets strict safety standards for these environments.

2. Benefits of Certified Explosion-Proof Pendant Solutions

Certified explosion-proof pendant lights reduce ignition risk in flammable atmospheres, providing a significant safety margin. They support compliance with international regulations, lowering the chance of incidents and helping maintain long-term reliability and operational continuity.

For further insights into maintaining compliance and safety standards, we recommend reviewing our article on 《Service & Support》.

Selecting the Right Pendant Light Fittings for Your Project

This section outlines how to choose pendant light fittings with a focus on practical considerations, performance, and total lifecycle value.

1. Factors to Consider for Optimal Performance

Optimal performance depends on several factors. We look at light output to ensure adequate illumination and at energy efficiency, particularly with led light fittings, to manage operational costs. Temperature ratings must align with ambient conditions, and ease of maintenance helps limit downtime.

| Factor | Description | Importance |

|---|---|---|

| Light Output | Lumen output and beam angle | Ensures adequate visibility and coverage |

| Energy Efficiency | LED technology, power factor | Reduces electricity consumption and operating costs |

| Temperature Rating | Ambient temperature range | Guarantees reliable operation under extreme heat or cold |

| Maintenance | Design for easy access and component replacement | Minimizes downtime and labor costs |

Real-World Applications of Advanced Pendant Lighting

We highlight how WAROM’s pendant light fittings perform in challenging industrial settings, showing their effectiveness and our project experience.

1. Case Study: Oil and Gas Sector Lighting Solutions

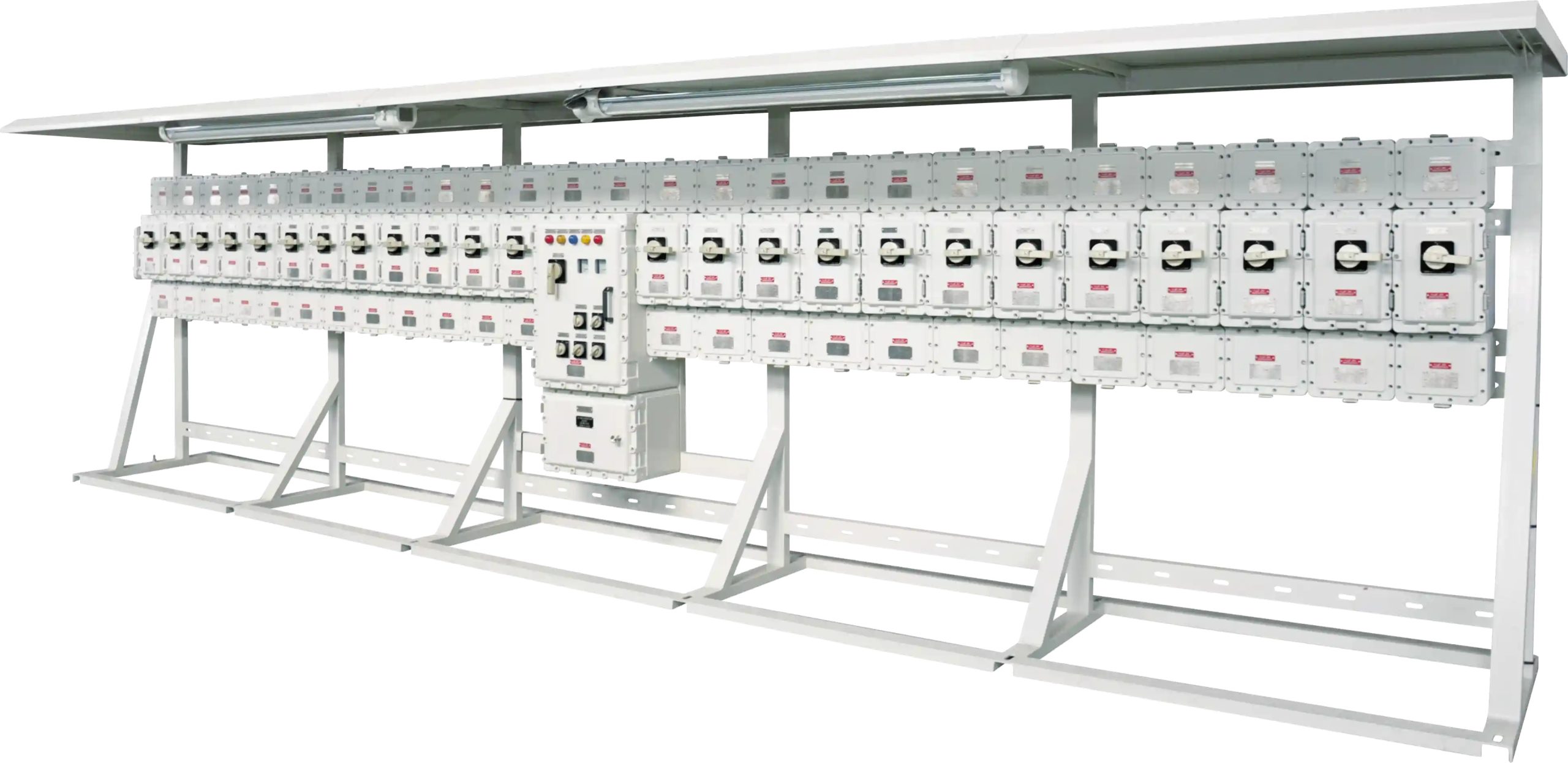

In the Tilenga project in Uganda, we supplied explosion proof light fittings explosion proof marine products and electrical equipment for wellpads, a Central Processing Facility (CPF), and pipelines. This project, partially located within Murchison Falls National Park, demanded zero safety incidents, energy efficiency, low maintenance, and reliability in extreme conditions. Our solutions met all safety, environmental, and performance requirements on schedule.

2. Case Study: Pharmaceutical Plant Lighting Innovations

For the Fushilai Pharmaceutical CM/CDMO Construction Project, we secured the bid for explosion-proof equipment. This included distribution boxes for workshops, warehouses, tank farms, and pump controls. Our early coordination with the promoter, design institute, and project owner ensured timely, high-quality execution. The project, launched in December 2023, strengthened customer trust and established a replicable model for complex industrial projects.

Call to Action

Ready to enhance safety and efficiency in your hazardous industrial environment? Contact WAROM TECHNOLOGY INCORPORATED COMPANY today for expert consultation and customized explosion-proof pendant light fitting solutions. Our team is available to discuss your project needs and provide a tailored proposal. Email: gmb@warom.com Tel: +86 21 39977076 +86 21 39972657

FAQs

1. What makes a pendant light fitting “explosion-proof”?

Explosion-proof pendant light fittings are specifically designed and certified to prevent internal explosions from igniting flammable gases, vapors, dusts, or fibers in the surrounding atmosphere. They typically feature robust enclosures, specialized sealing, and heat management systems to contain any sparks or explosions.

2. How do I determine the correct hazardous area classification for my facility?

Determining the correct hazardous area classification involves a detailed assessment of the facility’s processes, materials used, and potential for flammable releases. This process should be conducted by qualified engineers or safety professionals in accordance with international standards like ATEX or NEC.

3. What are the benefits of using LED technology in explosion-proof pendant lights?

LED technology offers several benefits for explosion-proof pendant lights, including significantly higher energy efficiency, longer lifespan, reduced maintenance costs, instant-on capabilities, and better light quality compared to traditional lighting sources. This contributes to lower operational costs and improved safety.

4. Can WAROM provide customized pendant light fitting solutions?

Yes, WAROM specializes in providing customized explosion-proof lighting and electrical systems. As demonstrated in our case studies, we work closely with clients, design institutes, and project owners to develop solutions that meet specific project requirements, environmental conditions, and regulatory standards.

5. What certifications should I look for in explosion-proof pendant light fittings?

For international projects, look for certifications such as ATEX (for Europe) and IECEx (for global acceptance), which ensure compliance with stringent safety standards for equipment used in hazardous locations. Other regional certifications like UL or EAC may also be required depending on the project’s location.

With over a decade of experience, he is a seasoned Explosion-Proof Electrical Engineer specializing in the design and manufacture of safety and explosion-proof products. He possesses in-depth expertise across key areas including explosion-proof systems, nuclear power lighting, marine safety, fire protection, and intelligent control systems. At Warom Technology Incorporated Company, he holds dual leadership roles as Deputy Chief Engineer for International Business and Head of the International R&D Department, where he oversees R&D initiatives and ensures the precise delivery of design documentation for international projects. Committed to advancing global industrial safety, he focuses on translating complex technologies into practical solutions, helping clients implement safer, smarter, and more reliable control systems worldwide.

Qi Lingyi